Page 228 - Mechanical Engineer's Data Handbook

P. 228

216 MECHANICAL ENGINEER’S DATA HANDBOOK

Allowable stress for welded structural steels \

Grade 43 50 55

Stress (N mm-’) 115 160 195

5.13 Limits and fits

It is impossible to make components the exact size and makes interchangeability possible.

an allowance or ‘tolerance’ must be made which British Standard BS 4500: Part 1 : 1969, ‘IS0 Limits

depends on the process and the application. The and Fits’, gives a comprehensive system relating to

tolerance results in two extremes of size which must be holes and shafts; it can, however, be used for other

maintained. The tolerances of two fitting parts, e.g. a components, e.g. a key in a keyway.

shaft in a bearing, determines the type of ‘fit’ and

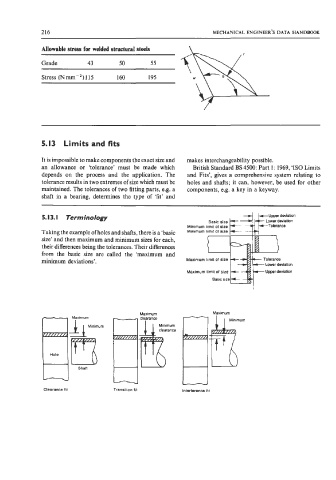

5.13. I Terminology Upper deviation

Lower deviation

Minimum limit Basic size size E-+ Tolerance

of

Taking the example of holes and shafts, there is a ‘basic Minimum limit of size

size’ and then maximum and minimum sizes for each,

their differences being the tolerances. Their differences

from the basic size are called the ‘maximum and

minimum deviations’. Maximum limit 01 size nca

r deviation

Maximum limit of size r deviation

Basic size

Maximum Maximum

Minimum

mum

rance

Clearance fit Transition lit Interference fit