Page 230 - Mechanical Engineer's Data Handbook

P. 230

Engineering materials

~

6.1 Cast irons

~~~ ~

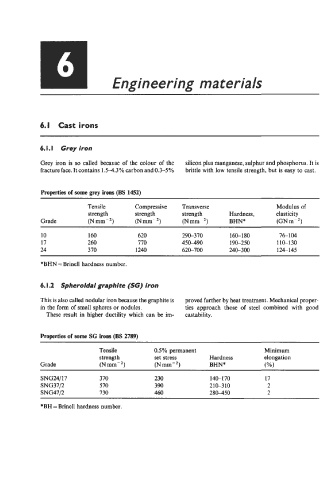

6. I. I Grey iron

Grey iron is so called because of the colour of the silicon plus manganese, sulphur and phosphorus. It is

fracture face. It contains 1.543% carbon and 0.3-5%0 brittle with low tensile strength, but is easy to cast.

Properties of some grey irons (BS 1452)

Tensile Compressive Transverse Modulus of

strength strength strength Hardness, elasticity

Grade (Nmm-2) (Nmm-*) (Nmm-’) BHN* (GN m-’)

10 160 620 2W370 160-180 76-104

17 260 770 450490 190-250 110-130

24 370 1240 620-700 240-300 124145

*BHN = Brinell hardness number.

6. I .2 Spheroidal graphite (SG) iron

This is also called nodular iron because the graphite is proved further by heat treatment. Mechanical proper-

in the form of small spheres or nodules. ties approach those of steel combined with good

These result in higher ductility which can be im- castability.

Properties of some SG irons (BS 2789)

Tensile 0.5% permanent Minimum

strength set stress Hardness elongation

Grade (Nmm-2) (Nmm-2) BHN* (%)

SNG24/17 370 230 140-170 17

SNG37/2 570 390 210-310 2

SNG47/2 730 460 280-450 2

*BH = Brinell hardness number.