Page 229 - Mechanical Engineer's Data Handbook

P. 229

MANUFACTURING TECHNOLOGY 217

Types of .fit 5.13.2 Selected Fits

The fit describes the manner in which two parts go BS 4500 ‘Selected Fits’ Gives a much smaller range of

together. A ‘clearance fit’ means that the shaft will fits, the hole tolerance is denoted by the letter H and

always be smaller than the hole. An ‘interference fit’ the shaft by a lower-case letter (see table). For

means that the shaft will always be larger than the hole conventionally manufactured parts, the five fits given

and a fitting force will be necessary. A ‘transition fit’ are usually sufficient (see table).

means that there may be either clearance or interfer-

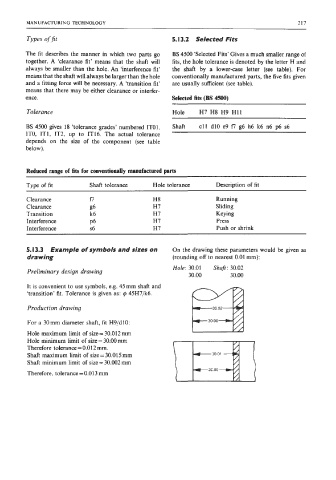

ence. selected fits (Bs 4500)

Tolerance Hole H7 H8 H9 H11

BS 4500 gives 18 ‘tolerance grades’ numbered ITO1, Shaft cll d10 e9 fl g6 h6 k6 n6 p6 s6

ITO, IT1, IT2, up to IT16. The actual tolerance

depends on the size of the component (see table

below).

Reduced range of fits for conventionally manufactured prts

_______~ ~~

Type of fit Shaft tolerance Hole tolerance Description of fit

Clearance fl H8 Running

Clearance g6 H7 Sliding

Transition k6 H7 Keying

Interference P6 H7 Press

Interference s6 H7 Push or shrink

5.13.3 Example of symbols and sizes on On the drawing these parameters would be given as

drawing (rounding off to nearest 0.01 mm):

Hole: 30.01 Shaft: 30.02

Preliminary design drawing

30.00 30.00

It is convenient to use symbols, e.g. 45 mm shaft and

‘transition’ fit. Tolerance is given as: 4 45H7/k6.

Production drawing

For a 30mm diameter shaft, fit H9/d10:

Hole maximum limit of size= 30.012 mm

Hole minimum limit of size = 30.00 mm

Therefore tolerance = 0.012 mm.

Shaft maximum limit of size = 30.015 mm

Shaft minimum limit of size = 30.002 mm

Therefore, tolerance = 0.01 3 mm