Page 233 - Mechanical Engineer's Data Handbook

P. 233

ENGINEERING MATERIALS 22 1

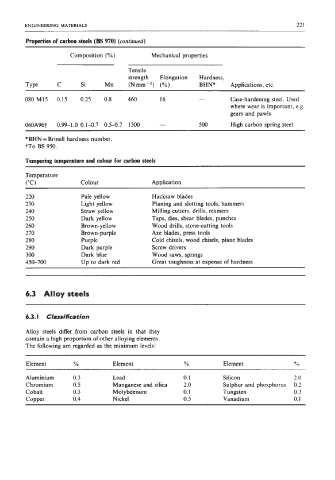

Properties of carbon steels (E 970) (continued)

Composition (YO) Mechanical properties

Tensile

strength Elongation Hardness,

Type C Si Mn (Nmm-*) (YO) BHN* Applications, etc.

080 M15 0.15 0.25 0.8 460 16 - Case-hardening steel. Used

where wear is important, e.g.

gears and pawls

060A96t 0.99-1.0 0.14.7 0.5-0.7 1300 - 500 High carbon spring steel

*BHN =Brinell hardness number.

tTo BS 950.

Tempering temperature and clolour for carbon steels

Temperature

("C) Colour Application

_____~

220 Pale yellow Hacksaw blades

230 Light yellow Planing and slotting tools, hammers

240 Straw yellow Milling cutters, drills, reamers

250 Dark yellow Taps, dies, shear blades, punches

260 Brown-yellow Wood drills, stone-cutting tools

270 Brown-purple Axe blades, press tools

280 Purple Cold chisels, wood chisels, plane blades

290 Dark purple Screw drivers

300 Dark blue Wood saws, springs

450-700 Up to dark red Great toughness at expense of hardness

6.3 Alloy steels

6.3. I Classification

Alloy steels differ from carbon steels in that they

contain a high proportion of other alloying elements.

The following are regarded as the minimum levels:

Element YO Element YO Element O/Q

Aluminium 0.3 Lead 0.1 Silicon 2 .o

Chromium 0.5 Manganese and silica 2.0 Sulphur and phosphorus 0.2

Cobalt 0.3 Molybdenum 0.1 Tungsten 0.3

Copper 0.4 Nickel 0.5 Vanadium 0.1