Page 238 - Mechanical Engineer's Data Handbook

P. 238

226 MECHANICAL ENGINEER’S DATA HANDBOOK

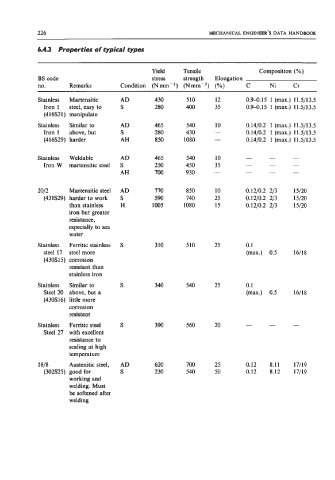

6.4.3 Properties of typical types

Yield Tensile Composition (YO)

BS code stress strength Elongation

no. Remarks Condition (Nmm-2) (Nmrn-?) (YO) C Ni Cr

Stainless Martensitic AD 430 5 10 12 0.9-0.15 1 (max.) 11.5/13.5

Iron 1 steel, easy to S 280 400 35 0.9-0.15 1 (max.) 11.5/13.5

(416821) manipulate

Stainless Similar to AD 465 540 10 0.14/0.2 1 (max.) 11.5/13.5

Iron 1 above, but S 280 430 - 0.1410.2 1 (max.) 11.51133

(416829) harder AH 850 1080 - 0.14/0.2 1 (max.) 11.5/13.5

Stainless Weldable AD 465 540 10 - - -

Iron W martensitic steel S 250 450 35 - - -

AH 700 930 - - - -

2012 Martensitic steel AD 770 850 10 0.1210.2 213 15/20

(43 1S29) harder to work S 590 740 25 0.1210.2 213 15/20

than stainless H 1005 1080 15 0.1210.2 213 15/20

iron but greater

resistance,

especially to sea

water

Stainless Ferritic stainless S 310 510 25 0.1

steel 17 steel more (max.) 0.5 16/18

(430S15) corrosion

resistant than

stainless iron

Stainless Similar to S 340 540 25 0.1

Steel 20 above, but a (max.) 0.5 16/18

(430316) little more

corrosion

resistant

Stainless Ferritic steel S 390 560 20 - - -

Steel 27 with excellent

resistance to

scaling at high

temperature

1818 Austenitic steel, AD 620 700 25 0.12 8.11 17/19

(302325) good for S 230 540 50 0.12 8.12 17/19

working and

welding. Must

be softened after

welding