Page 239 - Mechanical Engineer's Data Handbook

P. 239

ENGINEERING MATERULS 227

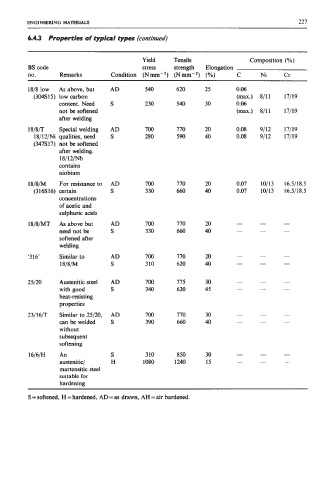

6.4.3 Proprties of typical types (contihued)

Yield Tensile Composition (YO)

BS code stress strength Elongation

no. Remarks Condition (Nmm-*) (Nmm-’) (%) C Ni Cr

1818 low As above, but AD 540 620 25 0.06

(304S15) low carbon (max.) 8/11 17/19

content. Need S 230 540 30 0.06

not be softened (max.) 8/11 17/19

after welding

18/8/r Special welding AD 700 770 20 0.08 9/12 17/19

18/12/Ni qualities, need S 280 590 40 0.08 9/12 17/19

(347317) not be softened

after welding.

18/12/Nb

contains

niobium

18/8/M For resistance to AD 700 770 20 0.07 10113 16.5/18.5

(316S16) certain S 330 660 40 0.07 10113 16.5/18.5

concentrations

of acetic and

sulphuric acids

18/8/MT As above but AD 700 770 20 - - -

need not be S 330 660 40 - - -

softened after

welding

‘316’ Similar to AD 700 770 20 - - -

18/8/M S 310 620 40 - - -

25/20 Austenitic steel AD 700 775 30 - - -

with good S 340 620 45 - - -

heat-resisting

properties

231 16/T Similar to 25/20, AD 700 770 30 - - -

canbewelded S 390 660 40 - - -

without

subsequent

softening

16/6/H An S 310 850 30 - - -

austenitic/ H 1080 1240 15 - - -

martensitic steel

suitable for

hardening -

S = softened, H =hardened, AD = as drawn, AH =air hardened.