Page 241 - Mechanical Engineer's Data Handbook

P. 241

ENGINEERING MATERIALS 229

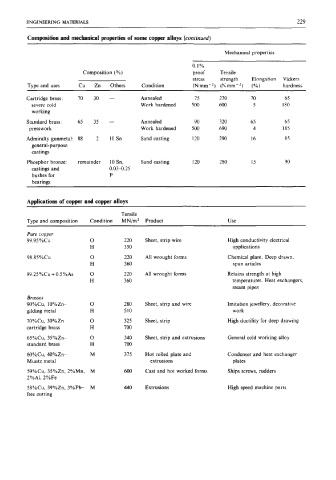

Composition and meclumiial properties of some copper alloys (continued)

Mechanical properties

0.1%

Composition (%) proof Tensile

stress strength Elongation Vickers

Type and uses Cu Zn Others Condition (Nmm-’) (Nmm-’) (%) hardness

Cartridge brass: 70 30 - Annealed 75 270 70 65

severe cold Work hardened 500 600 5 180

working

Standard brass: 65 35 - Annealed 90 320 65 65

presswork Work hardened 500 690 4 185

Admiralty gunmetal: 88 2 10 Sn Sand casting I20 290 16 85

general-purpose

castings

Phosphor bronze: remainder 10 Sn, Sand casting 120 280 15 90

castings and 0.034.25

bushes for P

bearings

Apdicatioas of copper and copper alloys

Tensile

Type and composition Condition MN/mz Product Use

Pure copper

99.95%Cu 0 220 Sheet, strip wire High conductivity electrical

H 3 50 applications

98.85%cu 0 220 All wrought forms Chemical plant. Deep drawn,

H 360 spun articles

99.25%cu +0.5%As 0 220 All wrought forms Retains strength at high

H 360 temperatures. Heat exchangers,

steam pipes

Brasses

9O%Cu, 10%Zn- 0 280 Sheet, strip and wire Imitation jewellery, decorative

gilding metal H 510 work

7o%cU, 30%Zn- 0 325 Sheet, strip High ductility for deep drawing

cartridge brass H 700

65%Cu, 35%Zn- 0 340 Sheet, strip and extrusions General cold working alloy

standard brass H 700

60%Cu, 40%Zn- M 375 Hot rolled plate and Condenser and heat exchanger

Muntz metal extrusions plates

59%Cu, 35%Zn, 2%Mn, M 600 Cast and hot worked forms Ships screws, rudders

2%A1, 2%Fe

58%Cu, 39%Zn, 3%Pb M 440 Extrusions High speed machine parts

free cutting