Page 242 - Mechanical Engineer's Data Handbook

P. 242

230 MECHANICAL ENGINEER'S DATA HANDBOOK

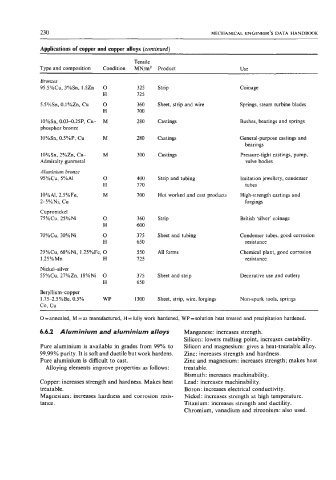

Applications of copper and copper alloys (continued)

Tensile

Type and composition Condition MN/m2 Product Use

Bronzes

95.5%Cu, 3%Sn, 1.5Zn 0 325 Strip Coinage

H 725

5.5%Sn, O.l%Zn, Cu 0 360 Sheet, strip and wire Springs, steam turbine blades

H 700

10%Sn, 0.03-0.25P, Cu- M 280 Castings Bushes, bearings and springs

phosphor bronze

10%Sn, O.S%P, Cu M 280 Castings General-purpose castings and

bearings

10%Sn, 2%Zn, Cu- M 300 Castings Pressure-tight castings, pump,

Admiralty gunmetal valve bodies

Aluminium bronze

95?'ocU, 5%AI 0 400 Strip and tubing Imitation jewellery, condenser

H 770 tubes

10Y0A1, 2.5%Fe, M 700 Hot worked and cast products High-strength castings and

2-5%Ni, Cu forgings

Cupronickel

75%cu, 25%Ni 0 360 Strip British 'silver' coinage

H 600

70%Cu, 30%Ni 0 375 Sheet and tubing Condenser tubes, good corrosion

H 650 resistance

29%cu, 68%Ni, 1.25%Fe, 0 550 All forms Chemical plant, good corrosion

1.25%Mn H 725 resistance

Nickel-silver

55%Cu, 27%Zn, l8%Ni 0 375 Sheet and strip Decorative use and cutlery

H 650

Ber y llium-copper

1.75-2.5%Be, 0.5% WP 1300 Sheet, strip, wire, forgings Non-spark tools, springs

co, cu

0 =annealed, M =as manufactured, H =fully work hardened, WP=solution heat treated and precipitation hardened.

6.6.2 Aluminium and aluminium alloys Manganese: increases strength.

Silicon: lowers melting point, increases castability.

Pure aluminium is available in grades from 99% to Silicon and magnesium: gives a heat-treatable alloy.

99.99% purity. It is soft and ductile but work hardens. Zinc: increases strength and hardness.

Pure aluminium is difficult to cast. Zinc and magnesium : increases strength; makes heat

Alloying elements improve properties as follows: treatable.

Bismuth: increases machinability.

Copper: increases strength and hardness. Makes heat Lead: increases machinability.

treatable. Boron: increases electrical conductivity.

Magnesium: increases hardness and corrosion resis- Nickel: increases strength at high temperature.

tance. Titanium: increases strength and ductility.

Chromium, vanadium and zirconium : also used.