Page 243 - Mechanical Engineer's Data Handbook

P. 243

ENGINEERING MATERIALS 23 1

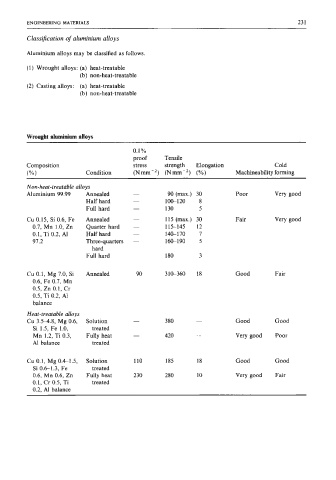

Classification of aluminium alloys

Aluminium alloys may be classified as follows.

(1) Wrought alloys: (a) heat-treatable

(b) non-heat-treatable

(2) Casting alloys: (a) heat-treatable

(b) non-heat-treatable

Wrought aluminium alloys

0.1 Yo

proof Tensile

Composition stress strength Elongation Cold

(%) Condition (Nmm-’) (Nmm-’) (X) Machineability forming

Non-heat-treatable alloys

Aluminium 99.99 Annealed - 90 (max.) 30 Poor Very good

Half hard - 100-120 8

Full hard - 130 5

Cu 0.15, Si 0.6, Fe Annealed - 115 (max.) 30 Fair Very good

0.7, Mn 1.0, Zn Quarter hard - 115-145 12

0.1, Ti 0.2, A1 Half hard - 140-170 7

97.2 Three-quarters - 16190 5

hard

Full hard 180 3

Cu 0.1, Mg 7.0, Si Annealed 90 3 le360 18 Good Fair

0.6, Fe 0.7, Mn

0.5, Zn 0.1, Cr

0.5, Ti 0.2, A1

balance

Heat-treatable alloys

Cu 3.548, Mg 0.6, Solution - 380 - Good Good

Si 1.5, Fe 1.0, treated

Mn 1.2, Ti 0.3, Fully heat - 420 - Very good Poor

AI balance treated

Cu 0.1, Mg 0.4-1.5, Solution 110 185 18 Good Good

Si 0.6-1.3, Fe treated

0.6, Mn 0.6, Zn Fully heat 230 280 10 Very good Fair

0.1, Cr 0.5, Ti treated

0.2, AI balance