Page 244 - Mechanical Engineer's Data Handbook

P. 244

232 MECHANICAL ENGINEER’S DATA HANDBOOK

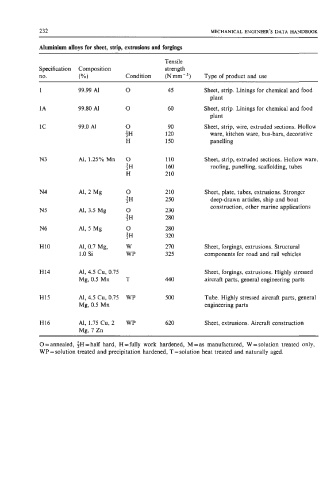

Aluminium alloys for sheet, strip, extrusions and forgings

Tensile

Specification Composition strength

no. (YO) Condition (Nmm-*) Type of product and use

1 99.99 AI 0 45 Sheet, strip. Linings for chemical and food

plant

1A 99.80 A1 0 60 Sheet, strip. Linings for chemical and food

plant

1c 99.0 AI 0 90 Sheet, strip, wire, extruded sections. Hollow

fH 120 ware, kitchen ware, bus-bars, decorative

H 150 panelling

N3 AI, 1.25% Mn 0 110 Sheet, strip, extruded sections. Hollow ware,

$H 160 roofing, panelling, scaffolding, tubes

H 210

N4 AI, 2 Mg 0 210 Sheet, plate, tubes, extrusions. Stronger

$H 250 deep-drawn articles, ship and boat

construction, other marine applications

N5 Al, 3.5 Mg 0 230

+H 280

N6 AI, 5 Mg 0 280

fH 320

H10 AI, 0.1 Mg, W 210 Sheet, forgings, extrusions. Structural

1.0 Si WP 325 components for road and rail vehicles

H14 AI, 4.5 Cu, 0.15 Sheet, forgings, extrusions. Highly stressed

Mg, 0.5 Mn T 440 aircraft parts, general engineering parts

H15 AI, 4.5 Cu, 0.15 WP 500 Tube. Highly stressed aircraft parts, general

Mg, 0.5 Mn engineering parts

H16 AI, 1.75 Cu, 2 WP 620 Sheet, extrusions. Aircraft construction

Mg, I Zn

0 =annealed, fH =half hard, H =fully work hardened, M = as manufactured, W = solution treated only,

WP = solution treated and precipitation hardened, T = solution heat treated and naturally aged.