Page 249 - Mechanical Engineer's Data Handbook

P. 249

ENGINEERING MATERIALS 237

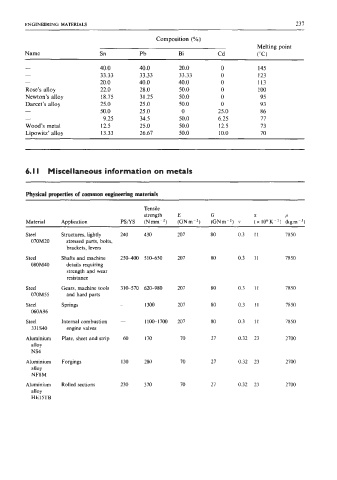

Composition (%)

Melting point

Name Sn Pb Bi Cd (“C)

- 40.0 40.0 20.0 0 145

- 33.33 33.33 33.33 0 123

- 20.0 40.0 40.0 0 113

Rose’s alloy 22.0 28.0 50.0 0 100

Newton’s alloy 18.75 31.25 50.0 0 95

Darcet’s alloy 25.0 25.0 50.0 0 93

- 50.0 25.0 0 25.0 86

- 9.25 34.5 50.0 6.25 77

Wood’s metal 12.5 25.0 50.0 12.5 73

Lipowitz’ alloy 13.33 26.67 50.0 10.0 70

6. I I Miscellaneous information on metals

~ ~~

Physical properties of common engineering materials

Tensile

strength E G U P

Material Application PS/YS (Nmm-2) (GNm-’) (GNm-2) v (x 106K-’) (kg~~-~)

Steel Structures, lightly 240 430 207 80 0.3 11 7850

070M20 stressed parts, bolts,

brackets, levers

Steel Shafts and machine 25MOO 510-650 207 80 0.3 11 7850

080M40 details requiring

strength and wear

resistance

Steel Gears, machine tools 31&570 620-980 207 80 0.3 I I 7850

070M55 and hard parts

Steel Springs - 1300 207 80 0.3 11 7850

060A96

Steel Internal combustion - 11W17OO 207 80 0.3 11 7850

331340 engine valves

Aluminium Plate, sheet and strip 60 170 70 27 0.32 23 2700

alloy

NS4

Aluminium Forgings 130 280 70 27 0.32 23 2700

alloy

NF8M

Aluminium Rolled sections 230 3 70 70 27 0.32 23 2700

alloy

HE 15TB