Page 250 - Mechanical Engineer's Data Handbook

P. 250

238 MECHANICAL ENGINEER’S DATA HANDBOOK

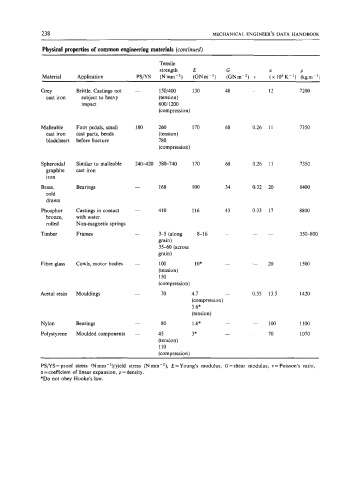

Physical properties of common engineering materials (continued)

Tensile

strength E G a P

Material Application PS/YS (Nmm-’) (GNm-’) (GNm-’) v (x 1O6K-*) (kgm-3)

Grey Brittle. Castings not - 150/400 130 48 - 12 7200

cast iron subject to heavy (tension)

impact 600/1200

(compression)

Malleable Foot pedals, small 180 260 170 68 0.26 11 7350

cast iron cast parts, bends (tension)

blackheart before fracture 780

(compression)

Spheroidal Similar to malleable 240-420 380-740 170 68 0.26 11 7350

graphite cast iron

iron

Brass, Bearings - 168 100 34 0.32 20 8400

cold

drawn

Phosphor Castings in contact 410 116 43 0.33 17 8800

bronze, with water.

rolled Nonmagnetic springs

Timber Frames - 3-5 (along 8-16 - _ - 350-800

grain)

35-60 (across

grain)

Fibre glass Cowls. motor bodies - 100 10. - - 20 1500

(tension)

150

(compression)

Acetal resin Mouldings - 70 4.7 - 0.35 13.5 1420

(compression)

3.6*

(tension)

Nylon Bearings - 80 1.6* __ - 100 1100

Polystyrene Moulded components - 45 3* - - 70 1070

(tension)

110

(compression)

PS/YS = proof stress (N mm-’)/yield stress (N mm-’), E = Young’s modulus, G = shear modulus, v = Poisson’s ratio,

a =coefficient of linear expansion, p =density.

*Do not obey Hooke’s law.