Page 247 - Mechanical Engineer's Data Handbook

P. 247

ENGINEERING MATERIALS 235

6.8 Spring materials

6.0.1 CPrbon steels 6.8.3 Non-ferrous alloys

Hard-drawn spring steel Spring brass (70/30)

Low cost; general purpose; low stress; low fatigue life. Low strength, but cheap and easily formed. Good

Temperatures below 120°C. Tensile strength up to electrical conductivity.

1600 N mm - '.

Phosphor bronze (5%Sn)

Piano (music) wire

High strength, resilience, corrosion resistance and

Tougher than harddrawn spring steel; high stress fatigue strength. Good electrical conductivity. Tensile

(tensile strength up to 2300 N inm- *); long fatigue life; strength 770N mm-'. Wire diameters 0.15-7mm.

used for 'small springs'. Temperatures below 120°C. Used for leaf and coil switch springs.

Oil-tempered spring steel Beryllium-copper (2$%)

General purpose springs; stress not too high; unsuit- Formed in soft condition and hardened. High tensile

able for shock or impact loads. Popular diameter strength. Used for current-carrying brush springs and

range 3-15 mm. contacts. Tensile strength 1300Nmm-2.

6.0.2 Alloy steels Inconel

Chrome-vanadium steel Nickel based alloy useful up to 370°C. Exceedingly

good corrosion resistance. Diameters up to 7mm.

Best for shock and impact loaL,. Available in oil- Tensile strength up to 1300Nmm-'.

tempered and annealed condition. Used for internal

combustion engine valve spriags. Temperatures up to 6.0.4 Moduli of spring materials

220 "C.

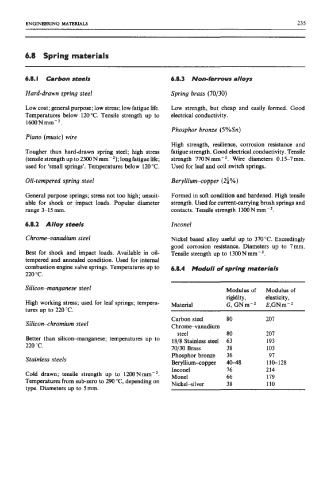

Silicon-manganese steel Modulus of Modulus of

rigidity, elasticity,

High working stress; used for leaf springs; tempera- Material G, GNm-' E,GNm-'

tures up to 220°C.

Carbon steel 80 207

Si1 icon-chromium steel Chromevanadium

steel 80 207

Better than silicon-manganese; temperatures up to 1818 Stainless steel 63 193

220 "C. 70130 Brass 38 103

Phosphor bronze 36 97

Stainless steels

Beryllium<opper 4048 110-128

Inconel 76 214

Cold drawn; tensile strength up to 1200Nmm-'. Monel 66 179

Temperatures from sub-zero to 290 "C, depending on Nickel-silver 38 110

type. Diameters up to 5mm.