Page 222 - Mechanical Engineer's Data Handbook

P. 222

210 MECHANICAL ENGINEER’S DATA HANDBOOK

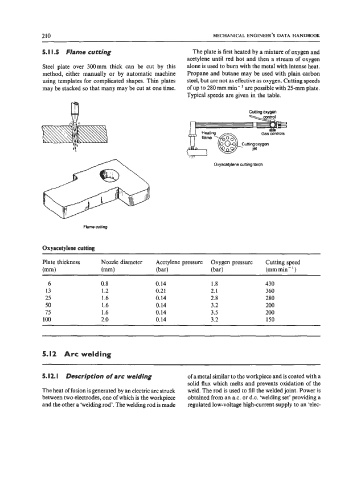

5. I I .5 Flame cutting The plate is first heated by a mixture of oxygen and

acetylene until red hot and then a stream of oxygen

Steel plate over 300mm thick can be cut by this alone is used to burn with the metal with intense heat.

method, either manually or by automatic machine Propane and butane may be used with plain carbon

using templates for complicated shapes. Thin plates steel, but are not as effective as oxygen. Cutting speeds

may be stacked so that many may be cut at one time. of up to 280 mm min- ’ are possible with 25-mm plate.

Typical speeds are given in the table.

Cutting oxygen

Oxyacetylene cutting torch

Flame cutting

Oxyacetylene cutting

Plate thickness Nozzle diameter Acetylene pressure Oxygen pressure Cutting speed

(mm) (mm) (bar) (bar) (mmmin-’)

6 0.8 0.14 1.8 430

13 1.2 0.21 2.1 360

25 1.6 0.14 2.8 280

50 1.6 0.14 3.2 200

75 1.6 0.14 3.5 200

100 2.0 0.14 3.2 150

5.12 Arc welding

5.12. I Description of arc welding of a metal similar to the workpiece and is coated with a

solid flux which melts and prevents oxidation of the

The heat of fusion is generated by an electric arc struck weld. The rod is used to fill the welded joint. Power is

between two electrodes, one of which is the workpiece obtained from an a.c. or d.c. ‘welding set’ providing a

and the other a ‘welding rod’. The welding rod is made regulated low-voltage high-current supply to an ‘elec-