Page 283 - Mechanical Engineer's Data Handbook

P. 283

ENGINEERING MEASUREMENTS 271

7.3 Strain measurement

In carrying out strength tests on materials it is ‘gauge length’ marked on the specimen. A typical

necessary to measure the strain. This is defined as the gauge length is 2 cm and the magnification is up to

extension divided by the original length. In the case of 2000.

mechanical extensometers, the original length is a

7.3. I Extensometer bridge circuit and the strain is measured by a gal-

vanometer or calibrated resistor. Dynamic strains may

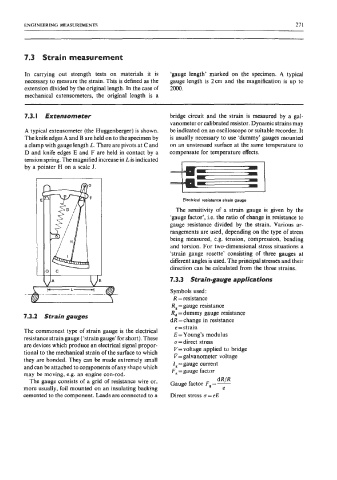

A typical extensometer (the Huggenberger) is shown. be indicated on an oscilloscope or suitable recorder. It

The knife edges A and B are held on to the specimen by is usually necessary to use ‘dummy’ gauges mounted

a clamp with gauge length L. There are pivots at C and on an unstressed surface at the same temperature to

D and knife edges E and F are held in contact by a compensate for temperature effects.

tension spring. The magnified increase in L is indicated

by a pointer H on a scale J. I i

Electrical resistance strain gauge

The sensitivity of a strain gauge is given by the

‘gauge factor’, i.e. the ratio of change in resistance to

gauge resistance divided by the strain. Various ar-

rangements are used, depending on the type of stress

being measured, e.g. tension, compression, bending

and torsion. For two-dimensional stress situations a

‘strain gauge rosette’ consisting of three gauges at

different angles is used. The principal stresses and their

direction can be calculated from the three strains.

JA 7.3.3 Strain-gauge applications

Symbols used:

Y- R =resistance

R, = gauge resistance

R, = dummy gauge resistance

7.3.2 Strain gauges

dR =change in resistance

e =strain

The commonest type of strain gauge is the electrical E = Young’s modulus

resistance strain gauge (‘strain gauge’ for short). These

n = direct stress

are devices which produce an electrical signal propor- V= voltage applied to bridge

tional to the mechanical strain of the surface to which P= galvanometer voltage

they are bonded. They can be made extremely small I, =gauge current

and can be attached to components ofany shape which F, =gauge factor

may be moving, e.g. an engine con-rod.

dR JR

The gauge consists of a grid of resistance wire or, Gauge factor F, = -

more usually, foil mounted on an insulating backing e

cemented to the component. Leads are connected to a Direct stress o=eE