Page 281 - Mechanical Engineer's Data Handbook

P. 281

ENGINEERING MEASUREMENTS 269

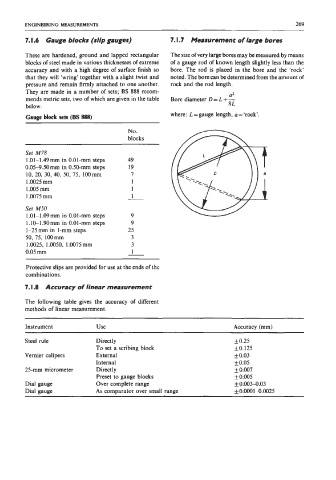

7. I .6 Gauge blocks (slip gauges) 7. I .7 Measurement of large bores

These are hardened, ground and lapped rectangular The size of very large bores may be measured by means

blocks of steel made in various thicknesses of extreme of a gauge rod of known length slightly less than the

accuracy and with a high degree of surface finish so bore. The rod is placed in the bore and the ‘rock’

that they will ‘wring’ together with a slight twist and noted. The bore can be determined from the amount of

pressure and remain firmly attached to one another. rock and the rod length.

They are made in a number of sets; BS 888 recom-

a’

mends metric sets, two of which are given in the table Bore diameter D = L + -

below. 8L

where: L = gauge length, a = ‘rock’.

Gauge Mock sets (BS 888)

No.

blocks

Set M78

1.01-1.49mm in 0.01-mm steps 49

0.05-9.50mm in 0.50-mm steps 19

10, 20, 30, 40, 50, 75, l00mm 7

1.0025 mm 1

1.005 mm 1

1.0075 mm -

1

Set M50

1.01-1.Wmm in 0.01-mm steps 9

1.10-1.90mm in 0.01-mm steps 9

1-25 mm in 1-mm steps 25

50, 75, l00mm 3

1.0025, 1.0050, 1.0075 mm 3

1

0.05 mm -

Protective slips are provided for use at the ends of the

combinations.

7. I .8 Accuracy of linear measurement

The following table gives the accuracy of different

methods of linear measurement.

Instrument Use Accuracy (mm)

Steel rule Directly f 0.25

To set a scribing block k0.125

Vernier calipers External k 0.03

Internal +_ 0.05

25-mm micrometer Directly f 0.007

Preset to gauge blocks k 0.005

Dial gauge Over complete range f 0.003-0.03

Dial gauge As comparator over small range fO.ooO1-0.0025