Page 297 - Mechanical Engineer's Data Handbook

P. 297

ENGINEERING MEASUREMENTS 285

Toothed wheel and

eleCIriCBl pick-up

and indiitor

7.9 Materials-testing measurements

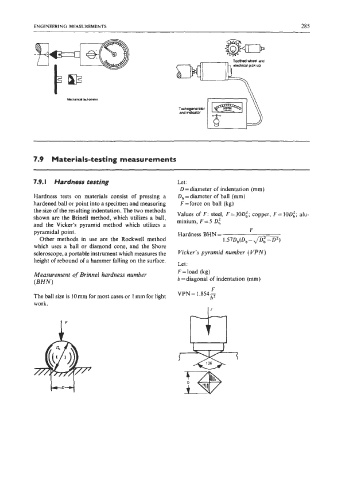

7.9. I Hardness testing Let :

D =diameter of indentation (mm j

Hardness tests on materials consist of pressing a D, = diameter of ball (mm)

hardened ball or point into a specimen and measuring F=force on ball (kg)

the size of the resulting indentation. The two methods

shown are the Brinell method, which utilizes a ball, Values of F: steel, F=300<; copper, F= 1OD<; alu-

and the Vicker's pyramid method which utilizes a minium, F = 5 0:

pyramidal point. Hardness BHN = F

Other methods in use are the Rockwell method 1 .57D,(D,- dm)

which uses a ball or diamond cone, and the Shore

scleroscope, a portable instrument which measures the Vicker's pyramid number (VPN)

height of rebound of a hammer falling on the surface.

Let:

Measurement of Brinnel hardness number F=load (kg)

(BHN) b = diagonal of indentation (mm)

F

The ball size is 10 mm for most cases or 1 mm for light VPN = 1.854 -

bZ

work.

I'