Page 293 - Mechanical Engineer's Data Handbook

P. 293

ENGINEERING MEASUREMENTS 28 1

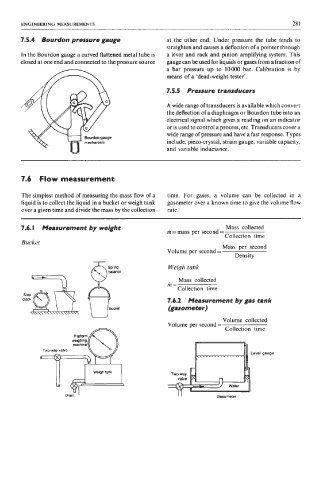

7.5.4 Bourdon pressure gauge at the other end. Under pressure the tube tends to

straighten and causes a deflection of a pointer through

In the Bourdon gauge a curved flattened metal tube is a lever and rack and pinion amplifying system. This

closed at one end and connected to the pressure source gauge can be used for liquids or gases from a fraction of

a bar pressure up to loo00 bar. Calibration is by

means of a ‘dead-weight tester’.

7.5.5 Pressure transducers

A wide range of transducers is available which convert

the deflection of a diaphragm or Bourdon tube into an

electrical signal which gives a reading on an indicator

or is used to control a process, etc. Transducers cover a

wide range of pressure and have a fast response. Types

include, piezo-crystal, strain gauge, variable capacity,

and variable inductance.

7.6 Flow measurement

The simplest method of measuring the mass flow of a time. For gases, a volume can be collected in a

liquid is to collect the liquid in a bucket or weigh tank gasometer over a known time to give the volume flow

over a given time and divide the mass by the collection rate.

7.6. I Measurement by weight Mass collected

riI = mass per second =

Collection time

Bucket

Mass per second

Volume per second =

Density

Weigh tank

Mass collected

m=

Collection time

7.6.2 Measurement by gas tank

(gasometer)

Volume collected

Volume per second =

Collection time

Two-way valve

Level

Weigh tank

Gasometer