Page 294 - Mechanical Engineer's Data Handbook

P. 294

282 MECHANICAL ENGINEER’S DATA HANDBOOK

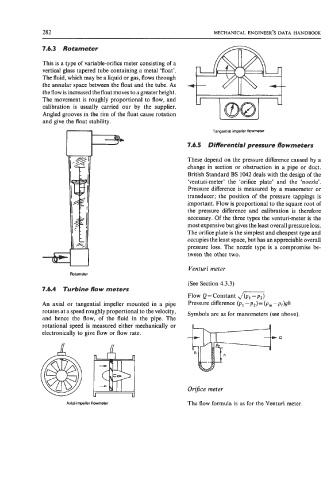

7.6.3 Rotameter

This is a type of variable-orifice meter consisting of a

vertical glass tapered tube containing a metal ‘float’.

The fluid, which may be a liquid or gas, flows through

the annular space between the float and the tube. As

the flow is increased the float moves to a greater height.

The movement is roughly proportional to flow, and

calibration is usually carried our by the supplier.

Angled grooves in the rim of the float cause rotation

and give the float stability.

Tangential-impeller flowmetel

l r - 7.6.5 Differential pressure flo wmeters

These depend on the pressure difference caused by a

change in section or obstruction in a pipe or duct.

British Standard BS 1042 deals with the design of the

‘venturi-meter’ the ‘orifice plate’ and the ‘nozzle’.

Pressure difference is measured by a manometer or

transducer; the position of the pressure tappings is

important. Flow is proportional to the square root of

the pressure difference and calibration is therefore

necessary. Of the three types the venturi-meter is the

most expensive but gives the least overall pressure loss.

The orifice plate is the simplest and cheapest type and

occupies the least space, but has an appreciable overall

pressure loss. The nozzle type is a compromise be-

tween the other two.

Venturi meter

Rotameter

(See Section 4.3.3)

7.6.4 Turbine flow meters Flow Q=Constant ,/m

An axial or tangential impeller mounted in a pipe Pressure difference (pl -p2)= (pm-pr)gh

rotates at a speed roughly proportional to the velocity, Symbols are as for manometers (see above).

and hence the flow, of the fluid in the pipe. The

rotational speed is measured either mechanically or

electronically to give flow or flow rate.

Orijice meter

Axial-impeller flowmeter The flow formula is as for the Venturi meter.