Page 593 - Mechanical Engineers' Handbook (Volume 2)

P. 593

584 Servoactuators for Closed-Loop Control

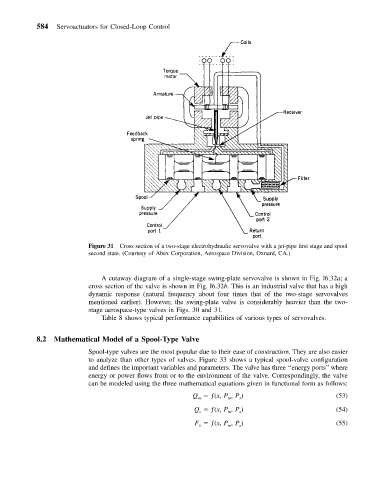

Figure 31 Cross section of a two-stage electrohydraulic servovalve with a jet-pipe first stage and spool

second state. (Courtesy of Abex Corporation, Aerospace Division, Oxnard, CA.)

A cutaway diagram of a single-stage swing-plate servovalve is shown in Fig. l6.32a;a

cross section of the valve is shown in Fig. l6.32b. This is an industrial valve that has a high

dynamic response (natural frequency about four times that of the two-stage servovalves

mentioned earlier). However, the swing-plate valve is considerably heavier than the two-

stage aerospace-type valves in Figs. 30 and 31.

Table 8 shows typical performance capabilities of various types of servovalves.

8.2 Mathematical Model of a Spool-Type Valve

Spool-type valves are the most popular due to their ease of construction. They are also easier

to analyze than other types of valves. Figure 33 shows a typical spool-valve configuration

and defines the important variables and parameters. The valve has three ‘‘energy ports’’where

energy or power flows from or to the environment of the valve. Correspondingly, the valve

can be modeled using the three mathematical equations given in functional form as follows:

Q ƒ(x, P , P ) (53)

m

s

m

Q ƒ(x, P , P ) (54)

m

s

s

F ƒ(x, P , P ) (55)

v

s

m