Page 145 - Mechanical Engineers' Handbook (Volume 4)

P. 145

134 Exergy Analysis, Entropy Generation Minimization, and Constructal Theory

the result of the collision between the global objective and the global constraints. The gen-

eration of flow architecture is the means by which the flow system achieves its global ob-

jective under the constraints.

In recent years, this activity of thermodynamic optimization through the selection of

flow configuration has become more focused on the end result, which is the generation of

the architecture of the flow system. 1,5 This is particularly evident in modern computational

heat and fluid flow, where large numbers of flow configurations can be simulated, compared,

and optimized. The generation of flow architecture is a phenomenon at work everywhere,

not only in engineered flow systems but also in natural flow systems (animate and inanimate).

The universality of this observation was expressed in a compact statement (the constructal

law) that proclaims a natural tendency in time: the maximization of access for the currents

that flow through a morphing flow system. The thought that this principle can be used to

rationalize the occurrence of optimized flow structures in nature (e.g., tree networks, round

tubes) was named constructal theory. 1,5,10–12

In this section the constructal law is formulated in analytical and graphical terms that

6

are analogous to terms employed in thermodynamics. This formulation makes the univer-

sality of the constructal law more evident.

A flow system, or nonequilibrium thermodynamic system, is characterized by ‘‘prop-

erties’’ (constraints), such as total volume and total volume occupied by all the ducts. A flow

system is also characterized by ‘‘performance’’ (function, objective) and ‘‘flow structure’’

(configuration, layout, geometry, architecture). Unlike the black box of classical thermody-

namics, which represents a system at equilibrium, a flow system has performance and es-

pecially configuration. Each flow system has a drawing.

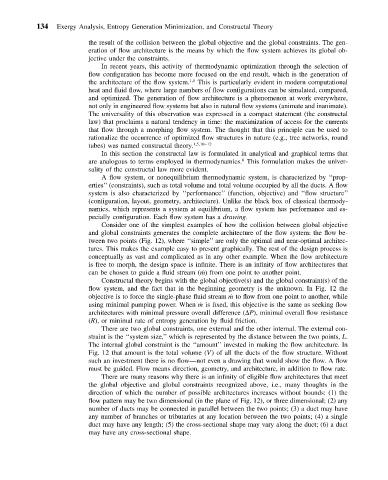

Consider one of the simplest examples of how the collision between global objective

and global constraints generates the complete architecture of the flow system: the flow be-

tween two points (Fig. 12), where ‘‘simple’’ are only the optimal and near-optimal architec-

tures. This makes the example easy to present graphically. The rest of the design process is

conceptually as vast and complicated as in any other example. When the flow architecture

is free to morph, the design space is infinite. There is an infinity of flow architectures that

can be chosen to guide a fluid stream ( ˙m) from one point to another point.

Constructal theory begins with the global objective(s) and the global constraint(s) of the

flow system, and the fact that in the beginning geometry is the unknown. In Fig. 12 the

objective is to force the single-phase fluid stream ˙m to flow from one point to another, while

using minimal pumping power. When ˙m is fixed, this objective is the same as seeking flow

architectures with minimal pressure overall difference ( P), minimal overall flow resistance

(R), or minimal rate of entropy generation by fluid friction.

There are two global constraints, one external and the other internal. The external con-

straint is the ‘‘system size,’’ which is represented by the distance between the two points, L.

The internal global constraint is the ‘‘amount’’ invested in making the flow architecture. In

Fig. 12 that amount is the total volume (V) of all the ducts of the flow structure. Without

such an investment there is no flow—not even a drawing that would show the flow. A flow

must be guided. Flow means direction, geometry, and architecture, in addition to flow rate.

There are many reasons why there is an infinity of eligible flow architectures that meet

the global objective and global constraints recognized above, i.e., many thoughts in the

direction of which the number of possible architectures increases without bounds: (1) the

flow pattern may be two dimensional (in the plane of Fig. 12), or three dimensional; (2) any

number of ducts may be connected in parallel between the two points; (3) a duct may have

any number of branches or tributaries at any location between the two points; (4) a single

duct may have any length; (5) the cross-sectional shape may vary along the duct; (6) a duct

may have any cross-sectional shape.