Page 282 - Mechanical Engineers' Handbook (Volume 4)

P. 282

12 Furnace Components in Complex Thermal Processes 271

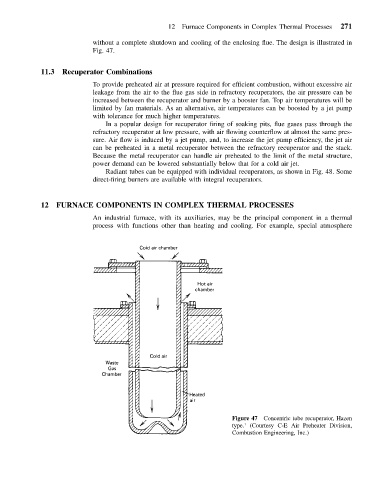

without a complete shutdown and cooling of the enclosing flue. The design is illustrated in

Fig. 47.

11.3 Recuperator Combinations

To provide preheated air at pressure required for efficient combustion, without excessive air

leakage from the air to the flue gas side in refractory recuperators, the air pressure can be

increased between the recuperator and burner by a booster fan. Top air temperatures will be

limited by fan materials. As an alternative, air temperatures can be boosted by a jet pump

with tolerance for much higher temperatures.

In a popular design for recuperator firing of soaking pits, flue gases pass through the

refractory recuperator at low pressure, with air flowing counterflow at almost the same pres-

sure. Air flow is induced by a jet pump, and, to increase the jet pump efficiency, the jet air

can be preheated in a metal recuperator between the refractory recuperator and the stack.

Because the metal recuperator can handle air preheated to the limit of the metal structure,

power demand can be lowered substantially below that for a cold air jet.

Radiant tubes can be equipped with individual recuperators, as shown in Fig. 48. Some

direct-firing burners are available with integral recuperators.

12 FURNACE COMPONENTS IN COMPLEX THERMAL PROCESSES

An industrial furnace, with its auxiliaries, may be the principal component in a thermal

process with functions other than heating and cooling. For example, special atmosphere

Figure 47 Concentric tube recuperator, Hazen

1

type. (Courtesy C-E Air Preheater Division,

Combustion Engineering, Inc.)