Page 452 - Mechanical Engineers' Handbook (Volume 4)

P. 452

6 Indirect Refrigeration 441

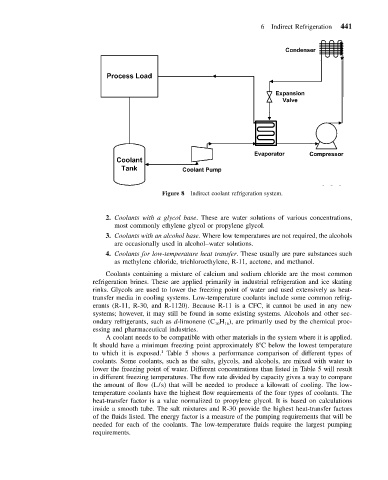

Figure 8 Indirect coolant refrigeration system.

2. Coolants with a glycol base. These are water solutions of various concentrations,

most commonly ethylene glycol or propylene glycol.

3. Coolants with an alcohol base. Where low temperatures are not required, the alcohols

are occasionally used in alcohol–water solutions.

4. Coolants for low-temperature heat transfer. These usually are pure substances such

as methylene chloride, trichloroethylene, R-11, acetone, and methanol.

Coolants containing a mixture of calcium and sodium chloride are the most common

refrigeration brines. These are applied primarily in industrial refrigeration and ice skating

rinks. Glycols are used to lower the freezing point of water and used extensively as heat-

transfer media in cooling systems. Low-temperature coolants include some common refrig-

erants (R-11, R-30, and R-1120). Because R-11 is a CFC, it cannot be used in any new

systems; however, it may still be found in some existing systems. Alcohols and other sec-

ondary refrigerants, such as d-limonene (C H ), are primarily used by the chemical proc-

10

16

essing and pharmaceutical industries.

A coolant needs to be compatible with other materials in the system where it is applied.

It should have a minimum freezing point approximately 8 C below the lowest temperature

to which it is exposed. Table 5 shows a performance comparison of different types of

1

coolants. Some coolants, such as the salts, glycols, and alcohols, are mixed with water to

lower the freezing point of water. Different concentrations than listed in Table 5 will result

in different freezing temperatures. The flow rate divided by capacity gives a way to compare

the amount of flow (L/s) that will be needed to produce a kilowatt of cooling. The low-

temperature coolants have the highest flow requirements of the four types of coolants. The

heat-transfer factor is a value normalized to propylene glycol. It is based on calculations

inside a smooth tube. The salt mixtures and R-30 provide the highest heat-transfer factors

of the fluids listed. The energy factor is a measure of the pumping requirements that will be

needed for each of the coolants. The low-temperature fluids require the largest pumping

requirements.