Page 449 - Mechanical Engineers' Handbook (Volume 4)

P. 449

438 Refrigeration

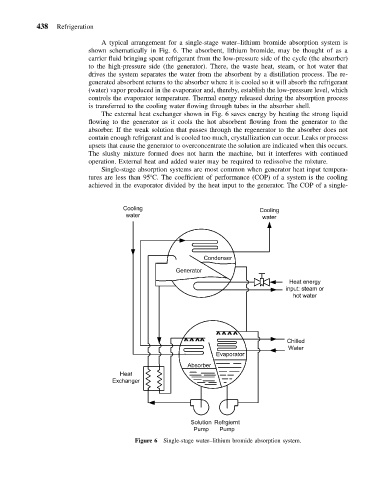

A typical arrangement for a single-stage water–lithium bromide absorption system is

shown schematically in Fig. 6. The absorbent, lithium bromide, may be thought of as a

carrier fluid bringing spent refrigerant from the low-pressure side of the cycle (the absorber)

to the high-pressure side (the generator). There, the waste heat, steam, or hot water that

drives the system separates the water from the absorbent by a distillation process. The re-

generated absorbent returns to the absorber where it is cooled so it will absorb the refrigerant

(water) vapor produced in the evaporator and, thereby, establish the low-pressure level, which

controls the evaporator temperature. Thermal energy released during the absorption process

is transferred to the cooling water flowing through tubes in the absorber shell.

The external heat exchanger shown in Fig. 6 saves energy by heating the strong liquid

flowing to the generator as it cools the hot absorbent flowing from the generator to the

absorber. If the weak solution that passes through the regenerator to the absorber does not

contain enough refrigerant and is cooled too much, crystallization can occur. Leaks or process

upsets that cause the generator to overconcentrate the solution are indicated when this occurs.

The slushy mixture formed does not harm the machine, but it interferes with continued

operation. External heat and added water may be required to redissolve the mixture.

Single-stage absorption systems are most common when generator heat input tempera-

tures are less than 95 C. The coefficient of performance (COP) of a system is the cooling

achieved in the evaporator divided by the heat input to the generator. The COP of a single-

Figure 6 Single-stage water–lithium bromide absorption system.