Page 465 - Mechanical Engineers' Handbook (Volume 4)

P. 465

454 Refrigeration

extremely high factors of safety on pressure stresses, eliminating the need for expensive

nickel steels from 59 to 29 C. Most designs are readily modified to provide suitable

materials for corrosion problems on the process side.

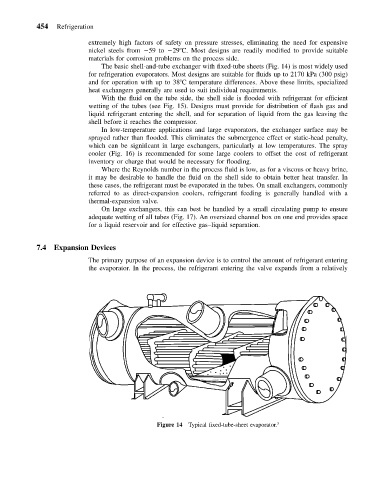

The basic shell-and-tube exchanger with fixed-tube sheets (Fig. 14) is most widely used

for refrigeration evaporators. Most designs are suitable for fluids up to 2170 kPa (300 psig)

and for operation with up to 38 C temperature differences. Above these limits, specialized

heat exchangers generally are used to suit individual requirements.

With the fluid on the tube side, the shell side is flooded with refrigerant for efficient

wetting of the tubes (see Fig. 15). Designs must provide for distribution of flash gas and

liquid refrigerant entering the shell, and for separation of liquid from the gas leaving the

shell before it reaches the compressor.

In low-temperature applications and large evaporators, the exchanger surface may be

sprayed rather than flooded. This eliminates the submergence effect or static-head penalty,

which can be significant in large exchangers, particularly at low temperatures. The spray

cooler (Fig. 16) is recommended for some large coolers to offset the cost of refrigerant

inventory or charge that would be necessary for flooding.

Where the Reynolds number in the process fluid is low, as for a viscous or heavy brine,

it may be desirable to handle the fluid on the shell side to obtain better heat transfer. In

these cases, the refrigerant must be evaporated in the tubes. On small exchangers, commonly

referred to as direct-expansion coolers, refrigerant feeding is generally handled with a

thermal-expansion valve.

On large exchangers, this can best be handled by a small circulating pump to ensure

adequate wetting of all tubes (Fig. 17). An oversized channel box on one end provides space

for a liquid reservoir and for effective gas–liquid separation.

7.4 Expansion Devices

The primary purpose of an expansion device is to control the amount of refrigerant entering

the evaporator. In the process, the refrigerant entering the valve expands from a relatively

Figure 14 Typical fixed-tube-sheet evaporator. 3