Page 79 - Mechanics of Microelectromechanical Systems

P. 79

66 Chapter 2

2. MICROCANTILEVERS

2.1 Introduction

The microcantilevers are used as sensing/actuation devices in a vast

range of applications that include nanoindentation, high-resolution optical

position detection, surface topology imaging, measurement/probing of

material elastic and strength properties, writing on surface topologies, high-

aspect ratio metrology, metallography, chemical/electrochemical

characterization, micro-lubrication/tribology, corrosion processes, cellular

engineering or grain growth and surface adhesion phenomena, as indicated

by Morita et al. [1], Chui [2], Lange et al. [3], as well as Gad-El-Hak [4],

Pelesko and Bernstein [5] or Madou [6], to name just a few works related to

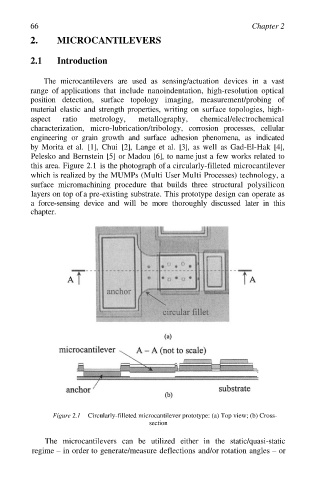

this area. Figure 2.1 is the photograph of a circularly-filleted microcantilever

which is realized by the MUMPs (Multi User Multi Processes) technology, a

surface micromachining procedure that builds three structural polysilicon

layers on top of a pre-existing substrate. This prototype design can operate as

a force-sensing device and will be more thoroughly discussed later in this

chapter.

Figure 2.1 Circularly-filleted microcantilever prototype: (a) Top view; (b) Cross-

section

The microcantilevers can be utilized either in the static/quasi-static

regime – in order to generate/measure deflections and/or rotation angles – or