Page 81 - Mechanics of Microelectromechanical Systems

P. 81

68 Chapter 2

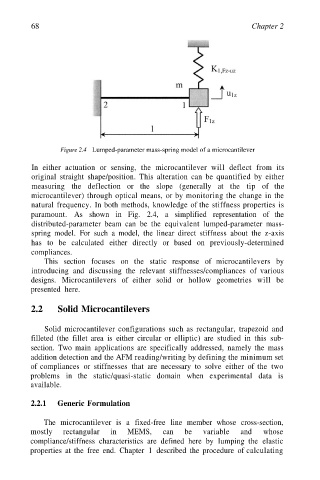

Figure 2.4 Lumped-parameter mass-spring model of a microcantilever

In either actuation or sensing, the microcantilever will deflect from its

original straight shape/position. This alteration can be quantified by either

measuring the deflection or the slope (generally at the tip of the

microcantilever) through optical means, or by monitoring the change in the

natural frequency. In both methods, knowledge of the stiffness properties is

paramount. As shown in Fig. 2.4, a simplified representation of the

distributed-parameter beam can be the equivalent lumped-parameter mass-

spring model. For such a model, the linear direct stiffness about the z-axis

has to be calculated either directly or based on previously-determined

compliances.

This section focuses on the static response of microcantilevers by

introducing and discussing the relevant stiffnesses/compliances of various

designs. Microcantilevers of either solid or hollow geometries will be

presented here.

2.2 Solid Microcantilevers

Solid microcantilever configurations such as rectangular, trapezoid and

filleted (the fillet area is either circular or elliptic) are studied in this sub-

section. Two main applications are specifically addressed, namely the mass

addition detection and the AFM reading/writing by defining the minimum set

of compliances or stiffnesses that are necessary to solve either of the two

problems in the static/quasi-static domain when experimental data is

available.

2.2.1 Generic Formulation

The microcantilever is a fixed-free line member whose cross-section,

mostly rectangular in MEMS, can be variable and whose

compliance/stiffness characteristics are defined here by lumping the elastic

properties at the free end. Chapter 1 described the procedure of calculating