Page 121 - Mechatronics for Safety, Security and Dependability in a New Era

P. 121

Ch22-I044963.fm Page 105 Tuesday, August 1, 2006 3:32 PM

Tuesday, August

3:32 PM

1, 2006

Ch22-I044963.fm

Page 105

105

105

Step 2.2; According to the behavior definition, the system decides the system behavior that

includes action for designer and maintenance of the design information etc

4. UPSTREAM DESIGN STAGE REQUIREMENTS FOR PRINCIPAL ARCHITECTURE

During the upstream design stage, the main purpose is to achieve the functional requirements. Shapes,

positions, etc. are very simple or vague. However, this information is very important to achieve the

main requirements and should be observed in the subsequent design stages. Therefore, to support the

design process flow it is important to handle simple or vague information and to transmit this

information to the downstream process. Moreover, the case that a simple geometric element expresses

some function, that will become a more detailed model or a space function. Thus, handling this space

is one of the important items to support during the design process.

Geometrical simplicity consideration

At the upstream design stage, geometric elements express a sub-assembly or part, even if the

geometric element is very simple like a line or plane. For example, when a line shows an axis in the

upstream design stage, it is necessary to be able to set the design information to a line, surface

roughness, material type, weight limitation, etc.. Thus, the mechanism should have the capability to set

the design information to targets regardless of geometrical type, where geometrical type means edge,

face or solid. The principal architecture fulfills this functionality.

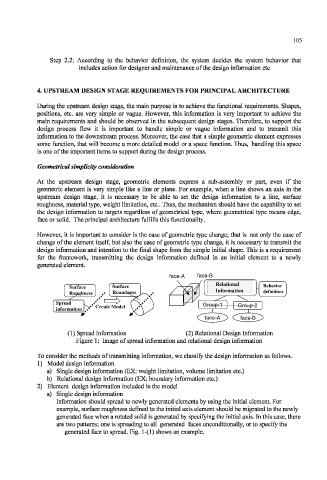

However, it is important to consider is the case of geometric type change; that is not only the case of

change of the element itself, but also the case of geometric type change, it is necessary to transmit the

design information and intention to the final shape from the simple initial shape. This is a requirement

for the framework, transmitting the design information defined in an initial element to a newly

generated element.

face-A face-B

Relational

Surface Surface Behavior

Roughness Roundness Information definition

Spread

Create Model Group-1 Group-2

information

face-A face-B

(1) Spread Information (2) Relational Design Information

Figure 1: Image of spread information and relational design information

To consider the methods of transmitting information, we classify the design information as follows.

1) Model design information

a) Single design information (EX: weight limitation, volume limitation etc.)

b) Relational design information (EX: boundary information etc.)

2) Element design information included in the model

a) Single design information

Information should spread to newly generated elements by using the initial element. For

example, surface roughness defined to the initial axis element should be migrated to the newly

generated face when a rotated solid is generated by specifying the initial axis. In this case, there

are two patterns; one is spreading to all generated faces unconditionally, or to specify the

generated face to spread. Fig. 1-(1) shows an example.