Page 146 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 146

120 Membranesfor Industrial Wastewater Recovery and Re-use

Dehydrator

Backnsshable

1

San mer

~

Filtered

water lank

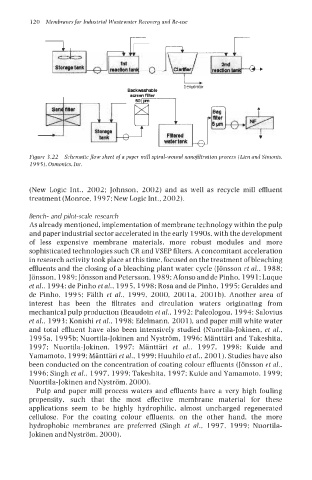

Figure 3.22 Schematic flow sheet of a paper mill spiral-wound nunofiltration process (Lien and Simonis.

1995), Osmonics, Inc.

(New Logic Int., 2002; Johnson, 2002) and as well as recycle mill effluent

treatment (Monroe, 1997; New LogicInt., 2002).

Bench- and pilot-scale research

As already mentioned, implementation of membrane technology within the pulp

and paper industrial sector accelerated in the early 1990s, with the development

of less expensive membrane materials, more robust modules and more

sophisticated technologies such CR and VSEP filters. A concomitant acceleration

in research activity took place at this time, focused on the treatment of bleaching

effluents and the closing of a bleaching plant water cycle (Jonsson et al., 1988;

Jonsson, 19 8 9; Jonsson and Petersson, 19 8 9; Afonso and de Pinho, 19 9 1 ; Luque

et al., 1994; de Pinho et al., 1995, 1998; Rosa and de Pinho, 1995; Geraldes and

de Pinho, 1995; Falth et al., 1999, 2000, 2001a, 2001b). Another area of

interest has been the filtrates and circulation waters originating from

mechanical pulp production (Beaudoin et al., 1992; Paleologou, 1994; Salovius

et al., 1993; Konishi et al., 1998; Edelmann, 2001). and paper mill white water

and total effluent have also been intensively studied (Nuortila-Jokinen, et al.,

1995a, 1995b; Nuortila-Jokinen and Nystrom, 1996; Manttari and Takeshita,

1997; Nuortila-Jokinen, 1997; Manttari et al., 1997, 1998; Kuide and

Yamamoto, 1999; Manttari et al., 1999; Huuhilo et al., 2001). Studies have also

been conducted on the concentration of coating colour effluents (Jonsson et al.,

1996; Singh et al., 1997, 1999; Takeshita, 1997; Kuide and Yamamoto, 1999;

Nuortila-Jokinen and Nystrom, 2000).

Pulp and paper mill process waters and effluents have a very high fouling

propensity, such that the most effective membrane material for these

applications seem to be highly hydrophilic, almost uncharged regenerated

cellulose. For the coating colour effluents, on the other hand, the more

hydrophobic membranes are preferred (Singh et aZ., 1997, 1999; Nuortila-

Jokinen and Nystrom, 2000).