Page 145 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 145

Industrial waters 11 9

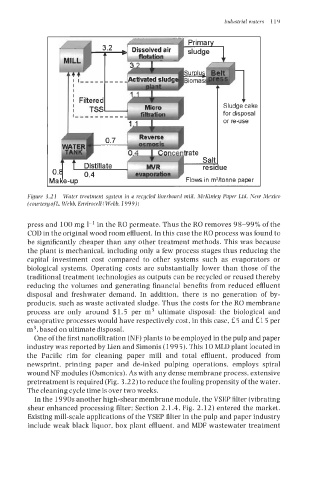

Figure 3.21 Water treatment system in a recycled linerboard mill, McKinley Paper Ltd, New Mexico

(courtesy of L. Webb, Envirocell (Webb, 1999))

press and 100 mg 1-1 in the RO permeate. Thus the RO removes 98-99% of the

COD in the original wood room effluent. In this case the RO process was found to

be significantly cheaper than any other treatment methods. This was because

the plant is mechanical, including only a few process stages thus reducing the

capital investment cost compared to other systems such as evaporators or

biological systems. Operating costs are substantially lower than those of the

traditional treatment technologies as outputs can be recycled or reused thereby

reducing the volumes and generating financial benefits from reduced effluent

disposal and freshwater demand. In addition, there is no generation of by-

products, such as waste activated sludge. Thus the costs for the RO membrane

process are only around $1.5 per m3 ultimate disposal: the biological and

evaoprative processes would have respectively cost, in this case, €5 and €1 5 per

m3, based on ultimate disposal.

One of the first nanofiltration (NF) plants to be employed in the pulp and paper

industry was reported by Lien and Simonis (1995). This 10 MLD plant located in

the Pacific rim for cleaning paper mill and total effluent, produced from

newsprint, printing paper and de-inked pulping operations, employs spiral

wound NF modules (Osmonics). As with any dense membrane process, extensive

pretreatment is required (Fig. 3.22) to reduce the fouling propensity of the water.

The cleaning cycle time is over two weeks.

In the 1990s another high-shear membrane module, the VSEP filter (vibrating

shear enhanced processing filter: Section 2.1.4, Fig. 2.12) entered the market.

Existing mill-scale applications of the VSEP filter in the pulp and paper industry

include weak black liquor, box plant effluent, and MDF wastewater treatment