Page 148 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 148

122 Membranesfor Industrial Wastewater Recoverg and Re-use

250

200

150

100

50

0

0.6 1.6 2.2 2.9

Amplitude, cm

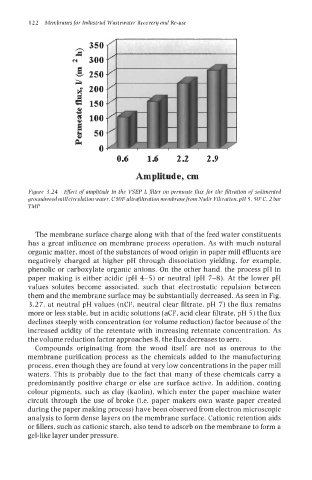

Figure 3.24 Efefert of amplitude in the VSEP L filter on permeate flux for the filtration of sedimented

groundwood mill circulation water. C30F ultrafiltration membrane from Nadir Filtration, pH 5, 50"C, 2 bar

TMP

The membrane surface charge along with that of the feed water constituents

has a great influence on membrane process operation. As with much natural

organic matter, most of the substances of wood origin in paper mill effluents are

negatively charged at higher pH through dissociation yielding, for example,

phenolic or carboxylate organic anions. On the other hand, the process pH in

paper making is either acidic (pH 4-5) or neutral (pH 7-8). At the lower pH

values solutes become associated, such that electrostatic repulsion between

them and the membrane surface may be substantially decreased. As seen in Fig.

3.27, at neutral pH values (nCF, neutral clear filtrate, pH 7) the flux remains

more or less stable, but in acidic solutions (aCF, acid clear filtrate, pH 5) the flux

declines steeply with concentration (or volume reduction) factor because of the

increased acidity of the retentate with increasing retentate concentration. As

the volume reduction factor approaches 8, the flux decreases to zero.

Compounds originating from the wood itself are not as onerous to the

membrane purification process as the chemicals added to the manufacturing

process, even though they are found at very low concentrations in the paper mill

waters. This is probably due to the fact that many of these chemicals carry a

predominantly positive charge or else are surface active. In addition, coating

colour pigments, such as clay (kaolin), which enter the paper machine water

circuit through the use of broke (i.e. paper makers own waste paper created

during the paper making process) have been observed from electron microscopic

analysis to form dense layers on the membrane surface. Cationic retention aids

or fillers, such as cationic starch, also tend to adsorb on the membrane to form a

gel-like layer under pressure.