Page 161 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 161

lndwtrial waters 13 5

Woven

Fabnc

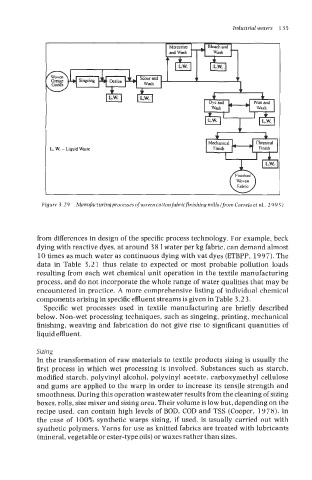

Figure 3.29 Manufacturingprocesseuofwovencottonfabricfinishing mills (from Correiaet al.. 199 5)

from differences in design of the specific process technology. For example, beck

dying with reactive dyes, at around 38 1 water per kg fabric, can demand almost

10 times as much water as continuous dying with vat dyes (ETBPP, 1997). The

data in Table 3.21 thus relate to expected or most probable pollution loads

resulting from each wet chemical unit operation in the textile manufacturing

process, and do not incorporate the whole range of water qualities that may be

encountered in practice. A more comprehensive listing of individual chemical

components arising in specific effluent streams is given in Table 3.2 3.

Specific wet processes used in textile manufacturing are briefly described

below. Non-wet processing techniques, such as singeing, printing, mechanical

finishing, weaving and fabrication do not give rise to significant quantities of

liquid effluent.

Sizing

In the transformation of raw materials to textile products sizing is usually the

first process in which wet processing is involved. Substances such as starch,

modified starch, polyvinyl alcohol, polyvinyl acetate, carboxymethyl cellulose

and gums are applied to the warp in order to increase its tensile strength and

smoothness. During this operation wastewater results from the cleaning of sizing

boxes, rolls, size mixer and sizing area. Their volume is low but, depending on the

recipe used, can contain high levels of BOD, COD and TSS (Cooper, 19 78). In

the case of 100% synthetic warps sizing, if used, is usually carried out with

synthetic polymers. Yarns for use as knitted fabrics are treated with lubricants

(mineral, vegetable or ester-type oils) or waxes rather than sizes.