Page 162 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 162

136 Membranesfor Industrial Wastewater Recoveru and Re-use

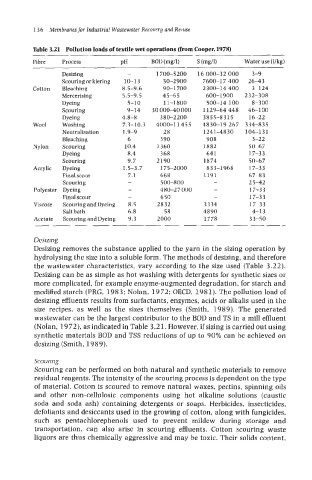

Table 3.21 Pollution loads of textile wet operations (from Cooper, 1978)

Desizing - 1700-5200 16 000-32 000 3-9

Scouring or kiering 10-13 50-2900 7600-17 400 26-43

Cotton Bleaching 8.5-9.6 90-1 700 2300-14 400 3-124

Mercerising 5.5-9.5 4 5-6 5 600-1 900 2 3 2-3 08

Dyeing 5-10 11-1 800 500-14 100 8-300

Scouring 9-14 30 000-40 000 1129-64448 46-100

Dyeing 4.8-8 3 80-2200 3855-8315 16-22

Wool Washing 7.3-10.3 4000-11 455 4830-19267 334-835

Neutralisation 1.9-9 28 1 2 4 1-48 30 104-131

Bleaching 6 3 90 908 3-2 2

Nylon Scouring 10.4 1360 1882 SO-67

Dyeing 8.4 368 641 17-33

Scouring 9.7 2190 1874 50-67

Acrylic Dyeing 1.5-3.7 175-2000 833-1968 17-33

Final scour 7.1 668 1191 67-83

Scouring - 500-800 - 2 5-42

Polyester Dyeing - 480-2 7 000 - 17-3 3

Final scour - 650 - 17-33

Viscose Scouring and Dyeing 8.5 2832 3334 17-33

Salt bath 6.8 58 4890 4-1 3

Acetate Scouring and Dyeing 9.3 2000 1778 3 3-SO

Desrzrng

Desizing removes the substance applied to the yarn in the sizing operation by

hydrolysing the size into a soluble form. The methods of desizing, and therefore

the wastewater characteristics, vary according to the size used (Table 3.22).

Desizing can be as simple as hot washing with detergents for synthetic sizes or

more complicated, for example enzyme-augmented degradation, for starch and

modified starch (PRG, 1983: Nolan, 1972; OECD, 1981). The pollution load of

desizing effluents results from surfactants, enzymes, acids or alkalis used in the

size recipes, as well as the sizes themselves (Smith, 1989). The generated

wastewater can be the largest contributor to the BOD and TS in a mill eMuent

(Nolan, 19 72). as indicated in Table 3.2 1. However, if sizing is carried out using

synthetic materials BOD and TSS reductions of up to 90% can be achieved on

desizing (Smith, 1989).

Scouring

Scouring can be performed on both natural and synthetic materials to remove

residual reagents. The intensity of the scouring process is dependent on the type

of material. Cotton is scoured to remove natural waxes, pectins, spinning oils

and other non-cellulosic components using hot alkaline solutions (caustic

soda and soda ash) containing detergents or soaps. Herbicides, insecticides,

defoliants and desiccants used in the growing of cotton, along with fungicides,

such as pentachlorephenols used to prevent mildew during storage and

transportation, can also arise in scouring effluents. Cotton scouring waste

liquors are thus chemically aggressive and may be toxic. Their solids content,