Page 210 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 210

Systern design aids 179

[ TWO Stage Concentrator I

-

,Two Parr with lnterparf Pump

, 1 wn Pars without lnlerpatr I'u

'-

VQL3'XJl

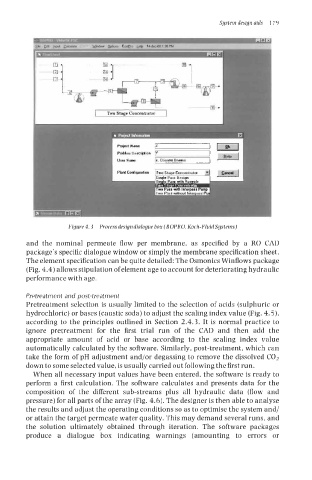

Figure 4.3 Process design dialogue box (ROPRO, Koch-Fluid Systems)

and the nominal permeate flow per membrane, as specified by a RO CAD

package's specific dialogue window or simply the membrane specification sheet.

The element specification can be quite detailed: The Osmonics Winflows package

(Fig. 4.4) allows stipulation of element age to account for deteriorating hydraulic

performance with age.

Pretreatment and post-treatment

Pretreatment selection is usually limited to the selection of acids (sulphuric or

hydrochloric) or bases (caustic soda) to adjust the scaling index value (Fig. 4.5),

according to the principles outlined in Section 2.4.3. It is normal practice to

ignore pretreatment for the first trial run of the CAD and then add the

appropriate amount of acid or base according to the scaling index value

automatically calculated by the software. Similarly, post-treatment, which can

take the form of pH adjustment and/or degassing to remove the dissolved C02

down to some selected value, is usually carried out following the first run.

When all necessary input values have been entered, the software is ready to

perform a first calculation. The software calculates and presents data for the

composition of the different sub-streams plus all hydraulic data (flow and

pressure) for all parts of the array (Fig. 4.6). The designer is then able to analyse

the results and adjust the operating conditions so as to optimise the system and/

or attain the target permeate water quality. This may demand several runs, and

the solution ultimately obtained through iteration. The software packages

produce a dialogue box indicating warnings (amounting to errors or