Page 215 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 215

184 Membranes for Industrial Wastewater Recovery and Re-use

-

ullel~3y Elrro MEMBRANE SYSTEMS

Edt Prewaw I I tern Detion 1 Desm 2 f

F C Process Informati

r r Arnmtiz%tnn

r r Itemized Capital 1,460,oDo.m 1,265,110aOO

r r Balana. of Cap$al 0.00 0.00

r c Membrane Element Replacent 96.MM.00 84.lXlO.00

r r Eneigy 119.46l.9O 148,324 90

r r Chemical Tteabnent [Dcisir@l 58.364.25 56,450 66

r r Cleaning 0.00 0 00

r c Labw 1ao.800 00 1 00,Boo.oo

r t Other Overhead and Maintenance 25.nOD.00 25,O 00

__ Eo-

j Detqnl--~ Design2 3 Design I Design 2 ---

Total Caatal I f.46O.OO0 00 1 265 o[)o OD Euro f m*3 Perm 1 D 180463 1 D 166820

"- .- -

KOCH Membrane System, ~IC 9 29 $1 41E22002

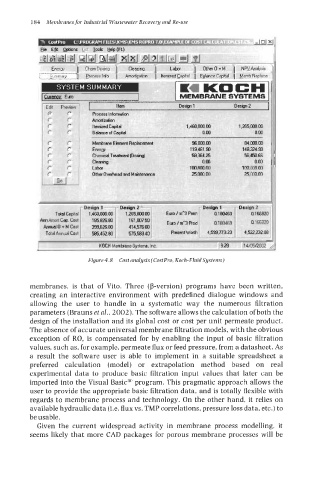

Figure 4.8 Cost analysis (Costpro, Koch-FZuidSystems)

membranes, is that of Vito. Three (p-version) programs have been written,

creating an interactive environment with predefined dialogue windows and

allowing the user to handle in a systematic way the numerous filtration

parameters (Brauns et al., 2002). The software allows the calculation of both the

design of the installation and its global cost or cost per unit permeate product.

The absence of accurate universal membrane filtration models, with the obvious

exception of RO, is compensated for by enabling the input of basic filtration

values, such as, for example, permeate flux or feed pressure, from a datasheet. As

a result the software user is able to implement in a suitable spreadsheet a

preferred calculation (model) or extrapolation method based on real

experimental data to produce basic filtration input values that later can be

imported into the Visual Basic@ program. This pragmatic approach allows the

user to provide the appropriate basic filtration data, and is totally flexible with

regards to membrane process and technology. On the other hand, it relies on

available hydraulic data (i.e. flux vs. TMP correlations, pressure loss data, etc.) to

be usable.

Given the current widespread activity in membrane process modelling, it

seems likely that more CAD packages for porous membrane processes will be