Page 79 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 79

Membrane technolog3 59

2.4.3 Fouling and pretreatment

Pretreatment is required to suppress fouling and/or clogging of membranes, or

else to remove chemically aggressive constituents such as chlorine. Clogging of

membrane channels by solid matter can, to some extent, be controlled

hydrodynamically, for a cross-flow process, or by the appropriate backflush

regime for a dead-end process. It is only for certain filtration processes and/or

specific duties, such as filtration of municipal or laundry wastewater, that

pretreatment to remove gross solids may be critical. In these examples it is the

filamentous matter that causes a problem, as it can form large aggregates which

can become tangled with hollow fibres or otherwise clog the membrane channels

and, for an immersed system, the aerators. Submerged membrane bioreactors for

sewage treatment thus routinely employ fine screens and/or microstrainers to

remove these materials.

Pretreatment of membrane filtration feedwaters can be analogous to that

employed for depth filtration. An example is the use of coagulants to assist in the

removal of natural organic matter (NOM) from upland surface waters.

Precoagulation increases overall NOM removal, thereby reducing the propensity

to form trihalomethanes, as well as producing a more permeable and less

adherent filter cake (Judd and Hillis, 2001).

The requirement for pretreatment is determined by the feedwater

concentration of:

0 suspended solids, and colloidal matter in particular,

0 scalants (sparingly soluble dissolved salts), and

0 microorganisms and nutrients.

The physical manifestation of these are briefly described in Table 2.13.

Appropriate pretreatment technology can normally only be identified through

pilot plant trials or through reference to appropriate case studies. However, in

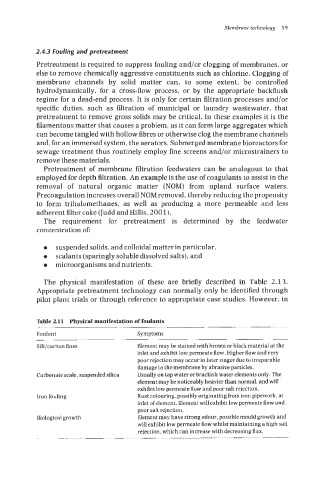

Table 2.13 Physical manifestation of foulants

Foulant Symptoms

Silt/carbon fines Element may be stained with brown or black material at the

inlet and exhibit low permeate flow. Higher flow and very

poor rejection may occur in later stages due to irreparable

damage to the membrane by abrasive particles.

Carbonate scale, suspended silica Usually on tap water or brackish water elements only. The

element may be noticeably heavier than normal, and will

exhibit low permeate flow and poor salt rejection.

Iron fouling Rust colouring. possibly originating from iron pipework, at

inlet ofelement. Element will exhibit low permeate flow and

poor salt rejection.

Biological growth Element may have strong odour, possible mould growth and

will exhibit low permeate flow whilst maintaining a high salt

rejection, which can increase with decreasing flux.