Page 44 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 44

26 Methods for Monitoring and Diagnosing the Efficiency of Catalytic Converters

Tests in [32] have clearly shown that converter performance in the form of HC conversion

efficiency was found to generally decrease when the sulhr content in the he1 used was

increased.

The catalyst activity after a certain vehicle mileage strongfy differs along the substrate length.

Typically, the front part of the substrate is deactivated much faster. On the one hand, poison

deposits occur in higher concentrations in this area, on the other hand, the reaction zone

located in the first few centimeters of the substrate results in higher structure temperatures.

It is also possible for the catalytic converters to be damaged during use, for instance by

fracturing causing leaks to the atmosphere of exhaust gas.

For all the above mentioned reasons, it is desirable to monitor the performance of catalytic

converters.

The present book refers to oii-board (OBI)) or iiori-OBD monitoring methods of the condition

of a catalytic converter installed in the exhaust pipe of an internal combustion engine vehicle.

The term “non-OBD means methods of monitoring taking place in workshops by specialized

technicians and special equipment. The term “on-board” means methods of monitoring taking

place during driving of the vehicle and being executed by the control unit of the vehicle. On-

board methods are the most recent ones and in some legislatures their application has become a

statutory requirement.

The first generation of on-board diagnostics (OBD I) was introduced by the state of California

in all vehicles sold by 1990. This first generation OBD did not monitor many important

emission control subsystems, such as the evaporative emissions system, the secondary air

injection and the catalytic converter.

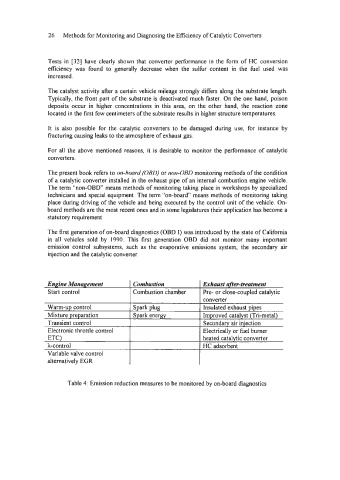

Table 4: Emission reduction measures to be monitored by on-board diagnostics