Page 88 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 88

70 Methods for Monitoring and Diagnosing the Efficiency of Catalytic Converters

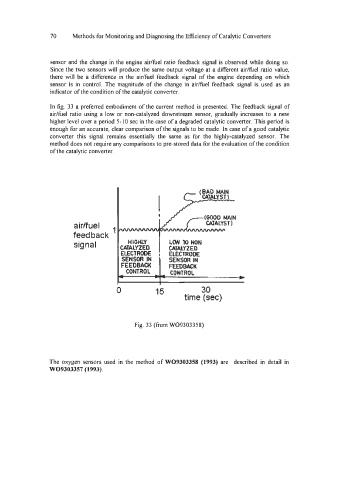

sensor and the change in the engine aidfuel ratio feedback signal is observed while doing so.

Since the two sensors will produce the same output voltage at a different aidfuel ratio value,

there will be a difference in the aidfie1 feedback signal of the engine depending on which

sensor is in control. The magnitude of the change in aidfuel feedback signal is used as an

indicator of the condition of the catalytic converter.

In fig. 33 a preferred embodiment of the current method is presented. The feedback signal of

aidfuel ratio using a low or non-catalyzed downstream sensor, gradually increases to a new

higher level over a period 5-10 sec in the case of a degraded catalytic converter. This period is

enough for an accurate, clear comparison of the signals to be made. In case of a good catalytic

converter this signal remains essentially the same as for the highly-catalyzed sensor. The

method does not require any comparisons to pre-stored data for the evaluation of the condition

of the catalytic converter.

(BAD MAIN

(GOOD MAIN

airfluel

..

H fGHLY I LOW TO NON

CATALYZED CATALYZED

ELECTRODE ELECTRODE

SENSOR IN i SENSOR IN

FEEDBACk

0 15 30

time (sec)

Fig. 33 (from W09303358)

The oxygen sensors used in the method of W09303358 (1993) are described in detail in

W09303357 (1 993).