Page 96 - A Practical Guide from Design Planning to Manufacturing

P. 96

72 Chapter Three

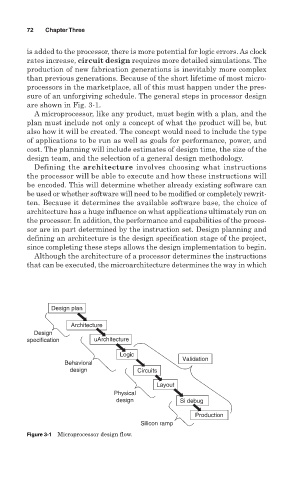

is added to the processor, there is more potential for logic errors. As clock

rates increase, circuit design requires more detailed simulations. The

production of new fabrication generations is inevitably more complex

than previous generations. Because of the short lifetime of most micro-

processors in the marketplace, all of this must happen under the pres-

sure of an unforgiving schedule. The general steps in processor design

are shown in Fig. 3-1.

A microprocessor, like any product, must begin with a plan, and the

plan must include not only a concept of what the product will be, but

also how it will be created. The concept would need to include the type

of applications to be run as well as goals for performance, power, and

cost. The planning will include estimates of design time, the size of the

design team, and the selection of a general design methodology.

Defining the architecture involves choosing what instructions

the processor will be able to execute and how these instructions will

be encoded. This will determine whether already existing software can

be used or whether software will need to be modified or completely rewrit-

ten. Because it determines the available software base, the choice of

architecture has a huge influence on what applications ultimately run on

the processor. In addition, the performance and capabilities of the proces-

sor are in part determined by the instruction set. Design planning and

defining an architecture is the design specification stage of the project,

since completing these steps allows the design implementation to begin.

Although the architecture of a processor determines the instructions

that can be executed, the microarchitecture determines the way in which

Design plan

Architecture

Design

specification uArchitecture

Logic

Validation

Behavioral

design Circuits

Layout

Physical

design Si debug

Production

Silicon ramp

Figure 3-1 Microprocessor design flow.