Page 57 - MODELING OF ASPHALT CONCRETE

P. 57

Modeling of Asphalt Binder Rheology and Its Application to Modified Binders 35

100 100

Unmodified

3 % SB

6 % SB

10 10

Starin at failure, % 1 Stress 1 Stress at failure, MPa

Strain

Test Temperature, °C

.1 .1

−35 −30 −25 −20 −15 −10 −5 0

(a) Modified with SB-Polymer

100 100

Unodified

CRM1

CRM2

10 10

Starin at failure, % 1 Stress 1 Stress at failure, MPa

Strain

Test Temperature, °C

.1 .1

−35 −30 −25 −20 −15 −10 −5 0

(b) Modified with crumb rubber

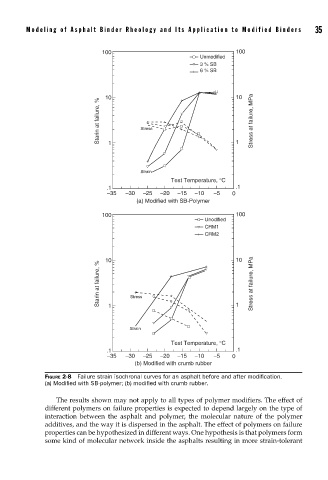

FIGURE 2-8 Failure strain isochronal curves for an asphalt before and after modifi cation.

(a) Modifi ed with SB-polymer; (b) modifi ed with crumb rubber.

The results shown may not apply to all types of polymer modifiers. The effect of

different polymers on failure properties is expected to depend largely on the type of

interaction between the asphalt and polymer, the molecular nature of the polymer

additives, and the way it is dispersed in the asphalt. The effect of polymers on failure

properties can be hypothesized in different ways. One hypothesis is that polymers form

some kind of molecular network inside the asphalts resulting in more strain-tolerant