Page 217 - Multidimensional Chromatography

P. 217

210 Multidimensional Chromatography

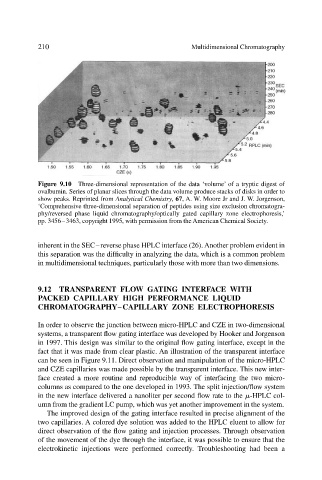

Figure 9.10 Three-dimensional representation of the data ‘volume’ of a tryptic digest of

ovalbumin. Series of planar slices through the data volume produce stacks of disks in order to

show peaks. Reprinted from Analytical Chemistry, 67, A. W. Moore Jr and J. W. Jorgenson,

‘Comprehensive three-dimensional separation of peptides using size exclusion chromatogra-

phy/reversed phase liquid chromatography/optically gated capillary zone electrophoresis,’

pp. 3456–3463, copyright 1995, with permission from the American Chemical Society.

inherent in the SEC–reverse phase HPLC interface (26). Another problem evident in

this separation was the difficulty in analyzing the data, which is a common problem

in multidimensional techniques, particularly those with more than two dimensions.

9.12 TRANSPARENT FLOW GATING INTERFACE WITH

PACKED CAPILLARY HIGH PERFORMANCE LIQUID

CHROMATOGRAPHY–CAPILLARY ZONE ELECTROPHORESIS

In order to observe the junction between micro-HPLC and CZE in two-dimensional

systems, a transparent flow gating interface was developed by Hooker and Jorgenson

in 1997. This design was similar to the original flow gating interface, except in the

fact that it was made from clear plastic. An illustration of the transparent interface

can be seen in Figure 9.11. Direct observation and manipulation of the micro-HPLC

and CZE capillaries was made possible by the transparent interface. This new inter-

face created a more routine and reproducible way of interfacing the two micro-

columns as compared to the one developed in 1993. The split injection/flow system

in the new interface delivered a nanoliter per second flow rate to the -HPLC col-

umn from the gradient LC pump, which was yet another improvement in the system.

The improved design of the gating interface resulted in precise alignment of the

two capillaries. A colored dye solution was added to the HPLC eluent to allow for

direct observation of the flow gating and injection processes. Through observation

of the movement of the dye through the interface, it was possible to ensure that the

electrokinetic injections were performed correctly. Troubleshooting had been a