Page 214 - Multidimensional Chromatography

P. 214

Multidimensional Electrodriven Separations 207

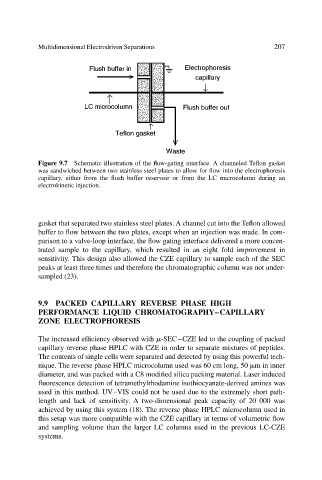

Figure 9.7 Schematic illustration of the flow-gating interface. A channeled Teflon gasket

was sandwiched between two stainless steel plates to allow for flow into the electrophoresis

capillary, either from the flush buffer reservoir or from the LC microcolumn during an

electrokinetic injection.

gasket that separated two stainless steel plates. A channel cut into the Teflon allowed

buffer to flow between the two plates, except when an injection was made. In com-

parison to a valve-loop interface, the flow gating interface delivered a more concen-

trated sample to the capillary, which resulted in an eight fold improvement in

sensitivity. This design also allowed the CZE capillary to sample each of the SEC

peaks at least three times and therefore the chromatographic column was not under-

sampled (23).

9.9 PACKED CAPILLARY REVERSE PHASE HIGH

PERFORMANCE LIQUID CHROMATOGRAPHY–CAPILLARY

ZONE ELECTROPHORESIS

The increased efficiency observed with -SEC–CZE led to the coupling of packed

capillary reverse phase HPLC with CZE in order to separate mixtures of peptides.

The contents of single cells were separated and detected by using this powerful tech-

nique. The reverse phase HPLC microcolumn used was 60 cm long, 50 m in inner

diameter, and was packed with a C8 modified silica packing material. Laser induced

fluorescence detection of tetramethylrhodamine isothiocyanate-derived amines was

used in this method. UV–VIS could not be used due to the extremely short path-

length and lack of sensitivity. A two-dimensional peak capacity of 20 000 was

achieved by using this system (18). The reverse phase HPLC microcolumn used in

this setup was more compatible with the CZE capillary in terms of volumetric flow

and sampling volume than the larger LC columns used in the previous LC-CZE

systems.