Page 104 - Book Hosokawa Nanoparticle Technology Handbook

P. 104

FUNDAMENTALS CH. 2 STRUCTURAL CONTROL OF NANOPARTICLES

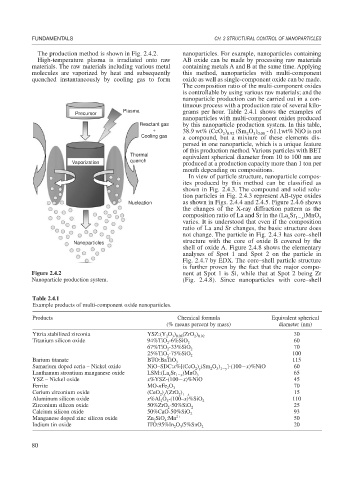

The production method is shown in Fig. 2.4.2. nanoparticles. For example, nanoparticles containing

High-temperature plasma is irradiated onto raw AB oxide can be made by processing raw materials

materials. The raw materials including various metal containing metals A and B at the same time. Applying

molecules are vaporized by heat and subsequently this method, nanoparticles with multi-component

quenched instantaneously by cooling gas to form oxide as well as single-component oxide can be made.

The composition ratio of the multi-component oxides

is controllable by using various raw materials; and the

nanoparticle production can be carried out in a con-

tinuous process with a production rate of several kilo-

Plasma

Precursor grams per hour. Table 2.4.1 shows the examples of

nanoparticles with multi-component oxides produced

Reactant gas by this nanoparticle production system. In this table,

+ 38.9 wt% (CeO ) (Sm O ) - 61.1wt% NiO is not

2

3 0.08

2 0.92

Cooling gas a compound, but a mixture of these elements dis-

persed in one nanoparticle, which is a unique feature

of this production method. Various particles with BET

Thermal equivalent spherical diameter from 10 to 100 nm are

Vaporization quench produced at a production capacity more than 1 ton per

month depending on compositions.

In view of particle structure, nanoparticle compos-

ites produced by this method can be classified as

shown in Fig. 2.4.3. The compound and solid solu-

tion particles in Fig. 2.4.3 represent AB-type oxides

Nucleation as shown in Figs. 2.4.4 and 2.4.5. Figure 2.4.6 shows

the changes of the X-ray diffraction pattern as the

composition ratio of La and Sr in the (La Sr 1 x )MnO 3

x

varies. It is understood that even if the composition

ratio of La and Sr changes, the basic structure does

not change. The particle in Fig. 2.4.3 has core–shell

Nanoparticles structure with the core of oxide B covered by the

shell of oxide A. Figure 2.4.8 shows the elementary

analyses of Spot 1 and Spot 2 on the particle in

Fig. 2.4.7 by EDX. The core–shell particle structure

is further proven by the fact that the major compo-

Figure 2.4.2 nent at Spot 1 is Si, while that at Spot 2 being Zr

Nanoparticle production system. (Fig. 2.4.8). Since nanoparticles with core–shell

Table 2.4.1

Example products of multi-component oxide nanoparticles.

Products Chemical formula Equivalent spherical

(% means percent by mass) diameter (nm)

Yttria stabilized zirconia YSZ:(Y O ) (ZrO ) 30

3 0.08

2 0.92

2

Titanium silicon oxide 94%TiO -6%SiO 2 60

2

67%TiO -33%SiO 2 70

2

25%TiO -75%SiO 2 100

2

Barium titanate BTO:BaTiO 3 115

Samarium doped ceria – Nickel oxide NiO–SDC:x%[(CeO ) (Sm O ) ]-(100 x)%NiO 60

3 1 y

2

2 y

Lanthanum strontium manganese oxide LSM:(La Sr 1 x )MnO 3 65

x

YSZ – Nickel oxide x%YSZ-(100 x)%NiO 45

Ferrite MO-nFe O 3 70

2

Cerium zirconium oxide (CeO ) /(ZrO ) 15

2 x

2 1 x

Aluminum silicon oxide x%Al O -(100–x)%SiO 2 110

3

2

Zirconium silicon oxide 50%ZrO -50%SiO 2 25

2

Calcium silicon oxide 50%CaO-50%SiO 2 93

Manganese doped zinc silicon oxide Zn SiO :Mn 2 50

2

4

Indium tin oxide ITO:95%In O /5%SnO 2 20

3

2

80