Page 272 - Book Hosokawa Nanoparticle Technology Handbook

P. 272

4.5 STRUCTURE CONTROL OF NANOPARTICLE COLLECTIVES BY SINTERING AND BONDING FUNDAMENTALS

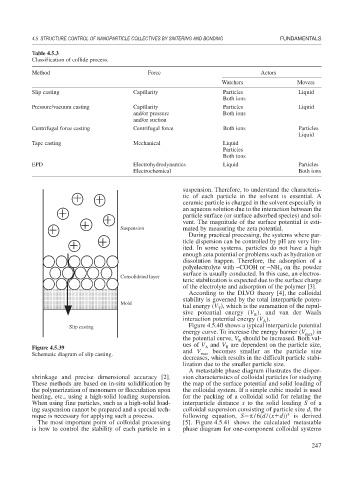

Table 4.5.3

Classification of collide process.

Method Force Actors

Watchers Movers

Slip casting Capillarity Particles Liquid

Both ions

Pressure/vacuum casting Capillarity Particles Liquid

and/or pressure Both ions

and/or suction

Centrifugal force casting Centrifugal force Both ions Particles

Liquid

Tape casting Mechanical Liquid

Particles

Both ions

EPD Electrohydrodynamics Liquid Particles

Electrochemical Both ions

suspension. Therefore, to understand the characteris-

tic of each particle in the solvent is essential. A

ceramic particle is charged in the solvent especially in

an aqueous solution due to the interaction between the

particle surface (or surface adsorbed species) and sol-

vent. The magnitude of the surface potential is esti-

Suspension mated by measuring the zeta potential.

During practical processing, the systems where par-

ticle dispersion can be controlled by pH are very lim-

ited. In some systems, particles do not have a high

enough zeta potential or problems such as hydration or

dissolution happen. Therefore, the adsorption of a

polyelectrolyte with –COOH or –NH on the powder

3

surface is usually conducted. In this case, an electros-

Consolidated layer

teric stabilization is expected due to the surface charge

of the electrolyte and adsorption of the polymer [3].

According to the DLVO theory [4], the colloidal

stability is governed by the total interparticle poten-

Mold

tial energy (V ), which is the summation of the repul-

T

sive potential energy (V ), and van der Waals

R

interaction potential energy (V ).

A

Figure 4.5.40 shows a typical interparticle potential

Slip casting

energy curve. To increase the energy barrier (V max ) in

the potential curve, V should be increased. Both val-

R

ues of V and V are dependent on the particle size,

R

Figure 4.5.39 and V A becomes smaller as the particle size

Schematic diagram of slip casting. max

decreases, which results in the difficult particle stabi-

lization due to the smaller particle size.

A metastable phase diagram illustrates the disper-

shrinkage and precise dimensional accuracy [2]. sion characteristics of colloidal particles for studying

These methods are based on in-situ solidification by the map of the surface potential and solid loading of

the polymerization of monomers or flocculation upon the colloidal system. If a simple cubic model is used

heating, etc., using a high-solid loading suspension. for the packing of a colloidal solid for relating the

When using fine particles, such as a high-solid load- interparticle distance x to the solid loading S of a

ing suspension cannot be prepared and a special tech- colloidal suspension consisting of particle size d, the

3

nique is necessary for applying such a process. following equation, S /6(d/(x d)) is derived

The most important point of colloidal processing [5]. Figure 4.5.41 shows the calculated metastable

is how to control the stability of each particle in a phase diagram for one-component colloidal systems

247