Page 536 - Book Hosokawa Nanoparticle Technology Handbook

P. 536

APPLICATIONS 22 DEVELOPMENT OF PHOTONIC CRYSTALS

diamond lattice made of silica spheres left after the

1 2

plasma process. The disappearance of alternative

spheres is easily recognized at the lowest row.

The optical properties of systems made of micros-

pheres are extensively studied only for both extreme

situations of isolated single spheres and periodical

array of infinite spheres. In contrast, the intermediate

4 3

systems between these two extremes have hardly

been investigated. Since the nanoparticle assembly

technique enables systematic experiments by varying

the number of the arranged spheres, it has been uti-

lized for the investigation of the intermediate

domains [16, 17].

Furthermore, stacking of plates is possible as well

[18]. Though the manipulation is currently carried out

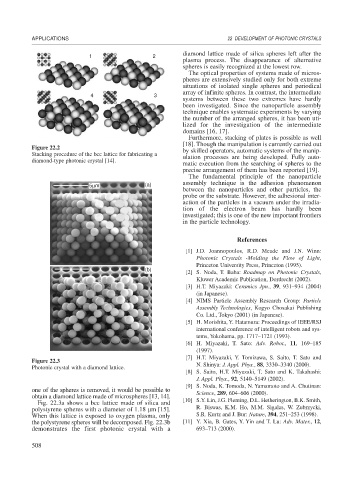

Figure 22.2 by skilled operators, automatic systems of the manip-

Stacking procedure of the bcc lattice for fabricating a ulation processes are being developed. Fully auto-

diamond-type photonic crystal [14].

matic execution from the searching of spheres to the

precise arrangement of them has been reported [19].

The fundamental principle of the nanoparticle

assembly technique is the adhesion phenomenon

5μm (a)

between the nanoparticles and other particles, the

probe or the substrate. However, the adhesional inter-

action of the particles in a vacuum under the irradia-

tion of the electron beam has hardly been

investigated; this is one of the new important frontiers

in the particle technology.

References

[1] J.D. Joannopoulos, R.D. Meade and J.N. Winn:

Photonic Crystals -Molding the Flow of Light,

Princeton University Press, Princeton (1995).

(b)

[2] S. Noda, T. Baba: Roadmap on Photonic Crystals,

Kluwer Academic Publication, Dordrecht (2002).

[3] H.T. Miyazaki: Ceramics Jpn., 39, 931–934 (2004)

(in Japanese).

[4] NIMS Particle Assembly Research Group: Particle

Assembly Technologies, Kogyo Chosakai Publishing

Co. Ltd., Tokyo (2001) (in Japanese).

[5] H. Morishita, Y. Hatamura: Proceedings of IEEE/RSJ

international conference of intelligent robots and sys-

tems, Yokohama, pp. 1717–1721 (1993).

[6] H. Miyazaki, T. Sato: Adv. Robot., 11, 169–185

(1997).

[7] H.T. Miyazaki, Y. Tomizawa, S. Saito, T. Sato and

Figure 22.3

Photonic crystal with a diamond lattice. N. Shinya: J. Appl. Phys., 88, 3330–3340 (2000).

[8] S. Saito, H.T. Miyazaki, T. Sato and K. Takahashi:

J. Appl. Phys., 92, 5140–5149 (2002).

[9] S. Noda, K. Tomoda, N. Yamamoto and A. Chutinan:

one of the spheres is removed, it would be possible to Science, 289, 604–606 (2000).

obtain a diamond lattice made of microspheres [13, 14].

Fig. 22.3a shows a bcc lattice made of silica and [10] S.Y. Lin, J.G. Fleming, D.L. Hetherington, B.K. Smith,

polystyrene spheres with a diameter of 1.18 m [15]. R. Biswas, K.M. Ho, M.M. Sigalas, W. Zubrzycki,

When this lattice is exposed to oxygen plasma, only S.R. Kurtz and J. Bur: Nature, 394, 251–253 (1998).

the polystyrene spheres will be decomposed. Fig. 22.3b [11] Y. Xia, B. Gates, Y. Yin and T. Lu: Adv. Mater., 12,

demonstrates the first photonic crystal with a 693–713 (2000).

508