Page 60 - Book Hosokawa Nanoparticle Technology Handbook

P. 60

1.10 MECHANICAL PROPERTY FUNDAMENTALS

strain

force (nN)

time (s)

stress (GPa)

strain

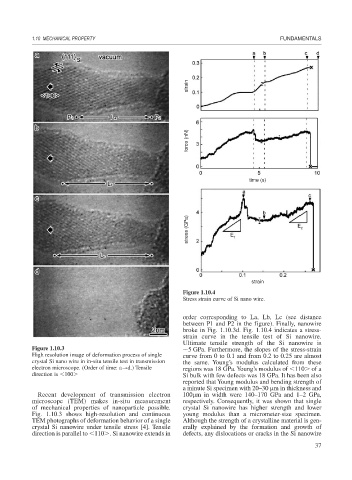

Figure 1.10.4

Stress strain curve of Si nano wire.

order corresponding to La, Lb, Lc (see distance

between P1 and P2 in the figure). Finally, nanowire

broke in Fig. 1.10.3d. Fig. 1.10.4 indicates a stress-

strain curve in the tensile test of Si nanowire.

Ultimate tensile strength of the Si nanowire is

Figure 1.10.3 5 GPa. Furthermore, the slopes of the stress-strain

High resolution image of deformation process of single curve from 0 to 0.1 and from 0.2 to 0.25 are almost

crystal Si nano wire in in-situ tensile test in transmission the same. Young’s modulus calculated from these

electron microscope. (Order of time: a d.) Tensile regions was 18 GPa. Young’s modulus of 110 of a

direction is 100 Si bulk with few defects was 18 GPa. It has been also

reported that Young modulus and bending strength of

a minute Si specimen with 20–30 m in thickness and

Recent development of transmission electron 100 m in width were 140–170 GPa and 1–2 GPa,

microscope (TEM) makes in-situ measurement respectively. Consequently, it was shown that single

of mechanical properties of nanoparticle possible. crystal Si nanowire has higher strength and lower

Fig. 1.10.3 shows high-resolution and continuous young modulus than a micrometer-size specimen.

TEM photographs of deformation behavior of a single Although the strength of a crystalline material is gen-

crystal Si nanowire under tensile stress [4]. Tensile erally explained by the formation and growth of

direction is parallel to 110 . Si nanowire extends in defects, any dislocations or cracks in the Si nanowire

37