Page 107 - New Trends In Coal Conversion

P. 107

70 New Trends in Coal Conversion

100

90

80

Amount of metals retained in different fractions, % 60

70

50

40

30

20

10

0

V Cr Mn Fe Co Ni Cu Zn As Se Cd Sn Sb Hg Ti Pb

Metals

Losses Emissions Fly ash Bottom ash

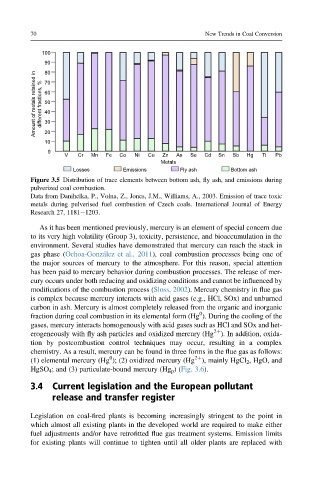

Figure 3.5 Distribution of trace elements between bottom ash, fly ash, and emissions during

pulverized coal combustion.

Data from Danihelka, P., Volna, Z., Jones, J.M., Williams, A., 2003. Emission of trace toxic

metals during pulverised fuel combustion of Czech coals. International Journal of Energy

Research 27, 1181e1203.

As it has been mentioned previously, mercury is an element of special concern due

to its very high volatility (Group 3), toxicity, persistence, and bioaccumulation in the

environment. Several studies have demonstrated that mercury can reach the stack in

gas phase (Ochoa-Gonz alez et al., 2011), coal combustion processes being one of

the major sources of mercury to the atmosphere. For this reason, special attention

has been paid to mercury behavior during combustion processes. The release of mer-

cury occurs under both reducing and oxidizing conditions and cannot be influenced by

modifications of the combustion process (Sloss, 2002). Mercury chemistry in flue gas

is complex because mercury interacts with acid gases (e.g., HCl, SOx) and unburned

carbon in ash. Mercury is almost completely released from the organic and inorganic

0

fraction during coal combustion in its elemental form (Hg ). During the cooling of the

gases, mercury interacts homogenously with acid gases such as HCl and SOx and het-

2þ

erogeneously with fly ash particles and oxidized mercury (Hg ). In addition, oxida-

tion by postcombustion control techniques may occur, resulting in a complex

chemistry. As a result, mercury can be found in three forms in the flue gas as follows:

0

2þ

(1) elemental mercury (Hg ); (2) oxidized mercury (Hg ), mainly HgCl 2 , HgO, and

HgSO 4 ; and (3) particulate-bound mercury (Hg p )(Fig. 3.6).

3.4 Current legislation and the European pollutant

release and transfer register

Legislation on coal-fired plants is becoming increasingly stringent to the point in

which almost all existing plants in the developed world are required to make either

fuel adjustments and/or have retrofitted flue gas treatment systems. Emission limits

for existing plants will continue to tighten until all older plants are replaced with