Page 103 - New Trends In Coal Conversion

P. 103

66 New Trends in Coal Conversion

volatile elements. Up to about 20% of the original mineral matter is collected in the

bottom ash and up to about 80% in the fly ash. The bottom ash remains in the combus-

tion area, whereas the fly ash is carried through the system. Nowadays power plants

have installed particle control devices with efficiencies higher than 99% such as elec-

trostatic precipitators or fabric filters (FFs). However, a small proportion, mostly fine

particles of less than about 10 mm in diameter, is emitted to the atmosphere with the

stack gases.

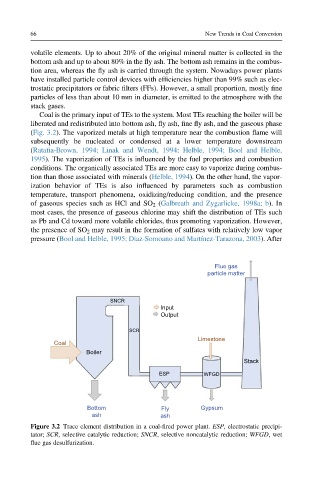

Coal is the primary input of TEs to the system. Most TEs reaching the boiler will be

liberated and redistributed into bottom ash, fly ash, fine fly ash, and the gaseous phase

(Fig. 3.2). The vaporized metals at high temperature near the combustion flame will

subsequently be nucleated or condensed at a lower temperature downstream

(Ratafia-Brown, 1994; Linak and Wendt, 1994: Helble, 1994; Bool and Helble,

1995). The vaporization of TEs is influenced by the fuel properties and combustion

conditions. The organically associated TEs are more easy to vaporize during combus-

tion than those associated with minerals (Helble, 1994). On the other hand, the vapor-

ization behavior of TEs is also influenced by parameters such as combustion

temperature, transport phenomena, oxidizing/reducing condition, and the presence

of gaseous species such as HCl and SO 2 (Galbreath and Zygarlicke, 1998a; b). In

most cases, the presence of gaseous chlorine may shift the distribution of TEs such

as Pb and Cd toward more volatile chlorides, thus promoting vaporization. However,

the presence of SO 2 may result in the formation of sulfates with relatively low vapor

pressure (Bool and Helble, 1995; Diaz-Somoano and Martínez-Tarazona, 2003). After

Flue gas

particle matter

SNCR

Input

Output

SCR

Limestone

Coal

Boiler

Stack

ESP WFGD

Bottom Fly Gypsum

ash ash

Figure 3.2 Trace element distribution in a coal-fired power plant. ESP, electrostatic precipi-

tator; SCR, selective catalytic reduction; SNCR, selective noncatalytic reduction; WFGD, wet

flue gas desulfurization.