Page 532 - New Trends in Eco efficient and Recycled Concrete

P. 532

480 New Trends in Eco-efficient and Recycled Concrete

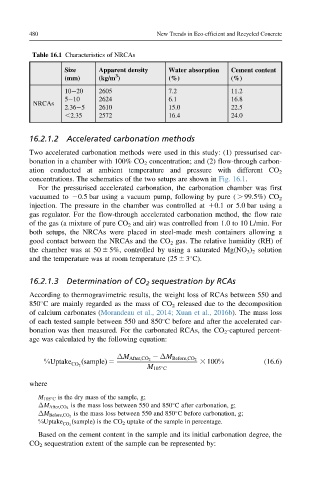

Table 16.1 Characteristics of NRCAs

Size Apparent density Water absorption Cement content

3

(mm) (kg/m ) (%) (%)

10 20 2605 7.2 11.2

5 10 2624 6.1 16.8

NRCAs

2.36 5 2610 15.0 22.5

,2.35 2572 16.4 24.0

16.2.1.2 Accelerated carbonation methods

Two accelerated carbonation methods were used in this study: (1) pressurised car-

bonation in a chamber with 100% CO 2 concentration; and (2) flow-through carbon-

ation conducted at ambient temperature and pressure with different CO 2

concentrations. The schematics of the two setups are shown in Fig. 16.1.

For the pressurised accelerated carbonation, the carbonation chamber was first

vacuumed to 20.5 bar using a vacuum pump, following by pure ( . 99.5%) CO 2

injection. The pressure in the chamber was controlled at 10.1 or 5.0 bar using a

gas regulator. For the flow-through accelerated carbonation method, the flow rate

of the gas (a mixture of pure CO 2 and air) was controlled from 1.0 to 10 L/min. For

both setups, the NRCAs were placed in steel-made mesh containers allowing a

good contact between the NRCAs and the CO 2 gas. The relative humidity (RH) of

the chamber was at 50 6 5%, controlled by using a saturated Mg(NO 3 ) 2 solution

and the temperature was at room temperature (25 6 3 C).

16.2.1.3 Determination of CO 2 sequestration by RCAs

According to thermogravimetric results, the weight loss of RCAs between 550 and

850 C are mainly regarded as the mass of CO 2 released due to the decomposition

of calcium carbonates (Morandeau et al., 2014; Xuan et al., 2016b). The mass loss

of each tested sample between 550 and 850 C before and after the accelerated car-

bonation was then measured. For the carbonated RCAs, the CO 2 -captured percent-

age was calculated by the following equation:

%Uptake ðsampleÞ 5 ΔM After;CO 2 2 ΔM Before;CO 2 3 100% (16.6)

CO 2

M 105 C

where

M 105 C is the dry mass of the sample, g;

is the mass loss between 550 and 850 C after carbonation, g;

ΔM After;CO 2

is the mass loss between 550 and 850 C before carbonation, g;

ΔM Before;CO 2

%Uptake ðsampleÞ is the CO 2 uptake of the sample in percentage.

CO 2

Based on the cement content in the sample and its initial carbonation degree, the

CO 2 sequestration extent of the sample can be represented by: