Page 86 - New Trends in Eco efficient and Recycled Concrete

P. 86

Recycled plastic 61

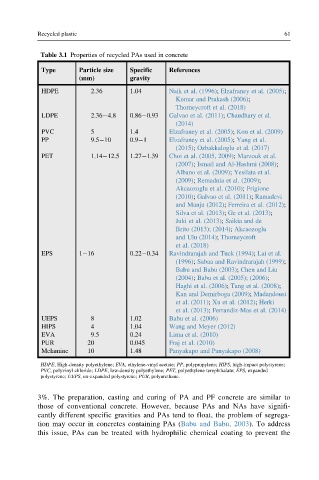

Table 3.1 Properties of recycled PAs used in concrete

Type Particle size Specific References

(mm) gravity

HDPE 2.36 1.04 Naik et al. (1996); Elzafraney et al. (2005);

Kumar and Prakash (2006);

Thorneycroft et al. (2018)

LDPE 2.36 4.8 0.86 0.93 Galvao et al. (2011); Chaudhary et al.

(2014)

PVC 5 1.4 Elzafraney et al. (2005); Kou et al. (2009)

PP 9.5 10 0.9 1 Elzafraney et al. (2005); Yang et al.

(2015); Ozbakkaloglu et al. (2017)

PET 1.14 12.5 1.27 1.39 Choi et al. (2005, 2009); Marzouk et al.

(2007); Ismail and Al-Hashmi (2008);

Albano et al. (2009); Yesilata et al.

(2009); Remadnia et al. (2009);

Akcaozoglu et al. (2010); Frigione

(2010); Galvao et al. (2011); Ramadevi

and Manju (2012); Ferreira et al. (2012);

Silva et al. (2013); Ge et al. (2013);

Juki et al. (2013); Saikia and de

Brito (2013); (2014); Akcaozoglu

and Ulu (2014); Thorneycroft

et al. (2018)

EPS 1 16 0.22 0.34 Ravindrarajah and Tuck (1994); Lai et al.

(1996); Sabaa and Ravindrarajah (1999);

Babu and Babu (2003); Chen and Liu

(2004); Babu et al. (2005); (2006);

Haghi et al. (2006); Tang et al. (2008);

Kan and Demirboga (2009); Madandoust

et al. (2011); Xu et al. (2012); Herki

et al. (2013); Ferrandiz-Mas et al. (2014)

UEPS 8 1.02 Babu et al. (2006)

HIPS 4 1.04 Wang and Meyer (2012)

EVA 9.5 0.24 Lima et al. (2010)

PUR 20 0.045 Fraj et al. (2010)

Melamine 10 1.48 Panyakapo and Panyakapo (2008)

HDPE, High-density polyethylene; EVA, ethylene-vinyl acetate; PP, polypropylene; HIPS, high-impact polystyrene;

PVC, polyvinyl chloride; LDPE, low-density polyethylene; PET, polyethylene terephthalate; EPS, expanded

polystyrene; UEPS, un-expanded polystyrene; PUR, polyurethane.

3%. The preparation, casting and curing of PA and PF concrete are similar to

those of conventional concrete. However, because PAs and NAs have signifi-

cantly different specific gravities and PAs tend to float, the problem of segrega-

tion may occur in concretes containing PAs (Babu and Babu, 2003). To address

this issue, PAs can be treated with hydrophilic chemical coating to prevent the